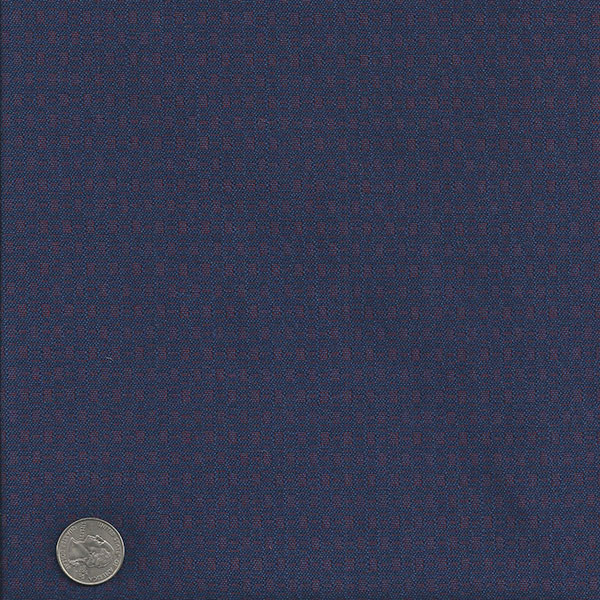

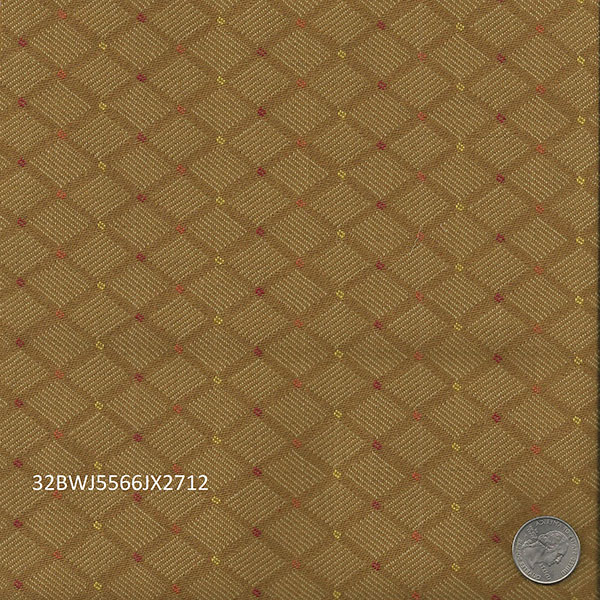

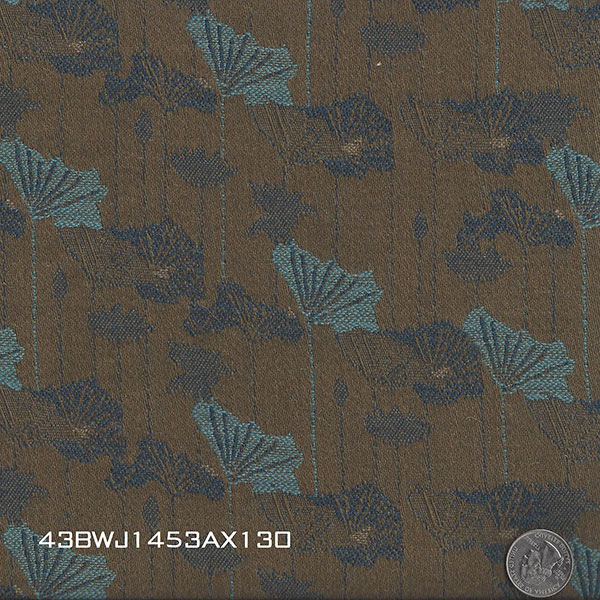

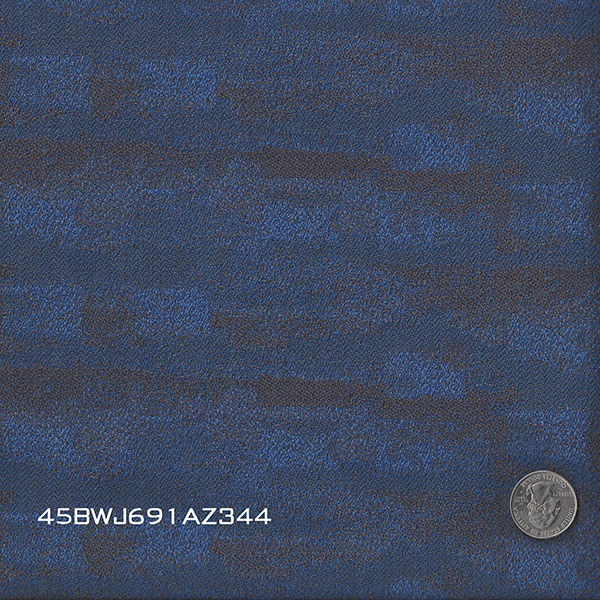

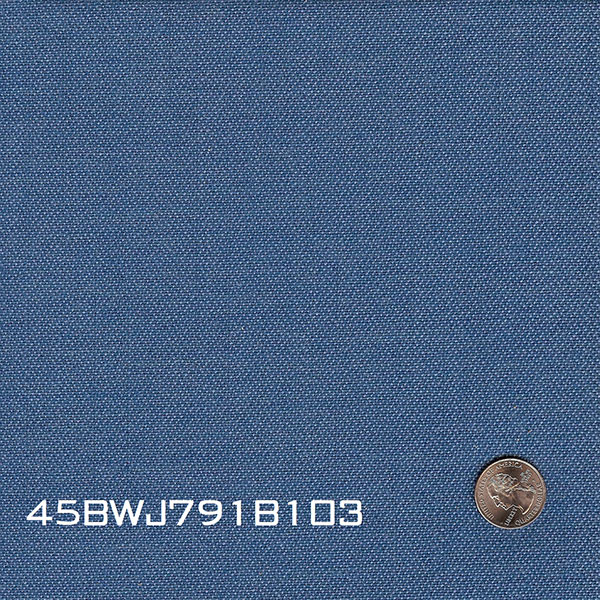

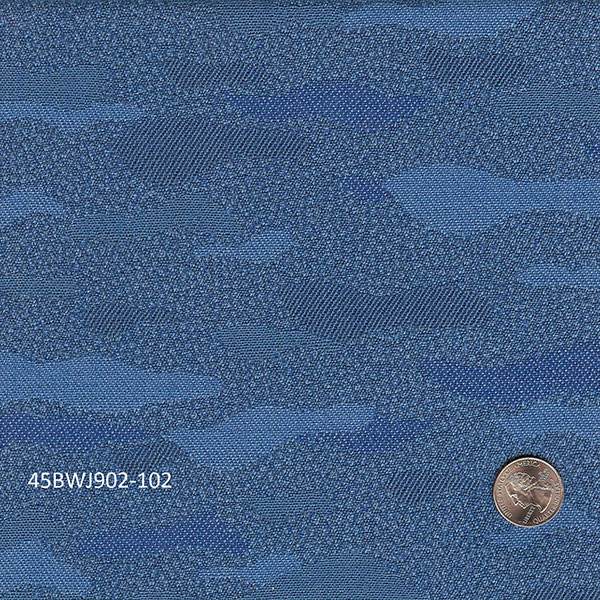

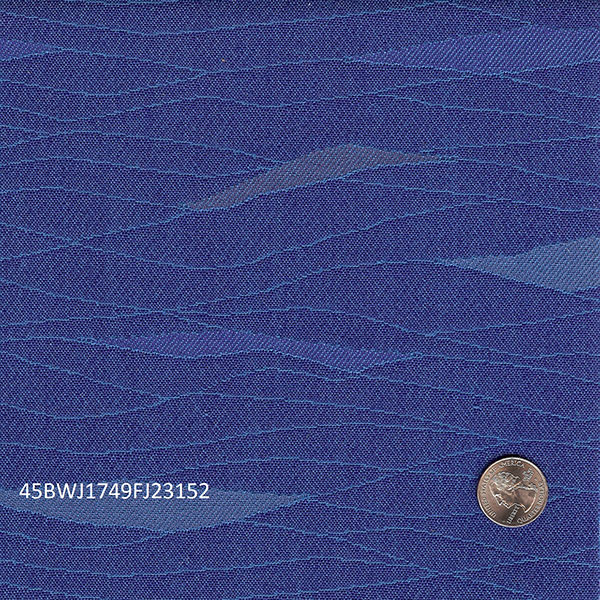

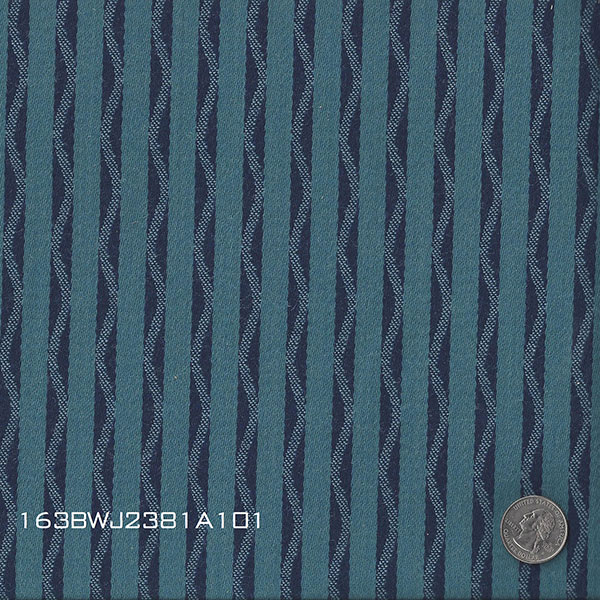

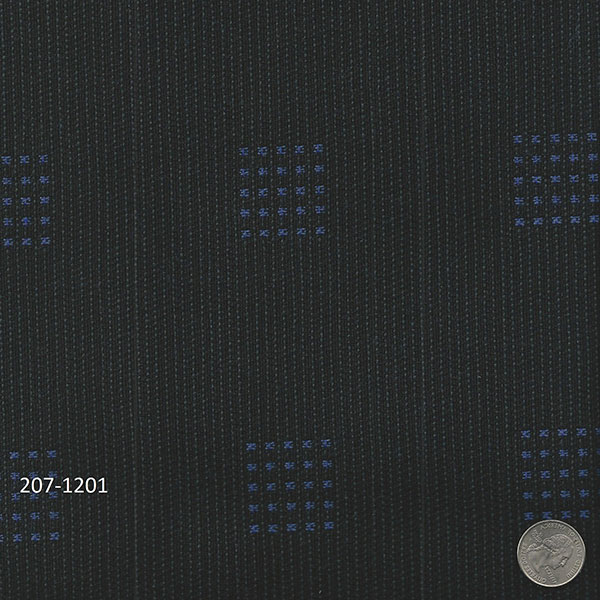

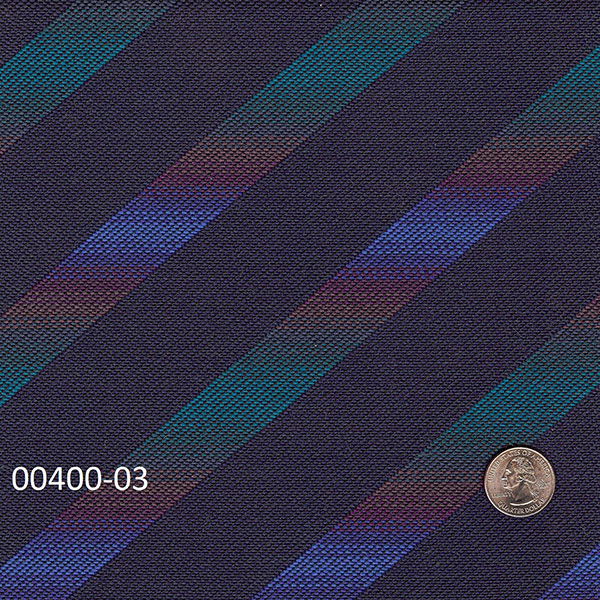

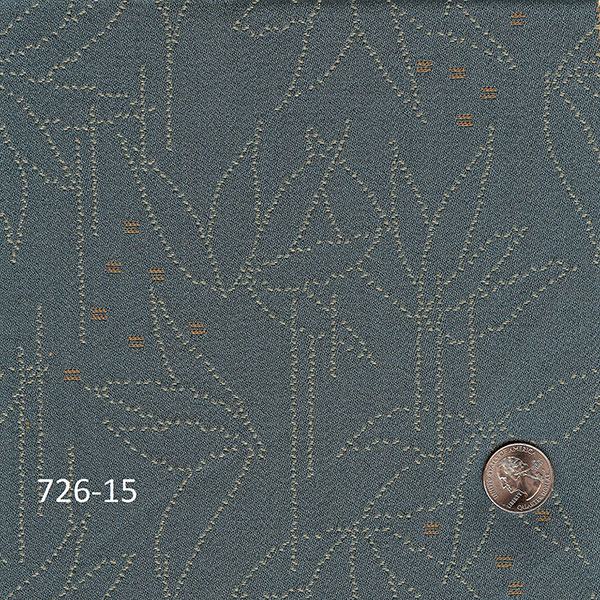

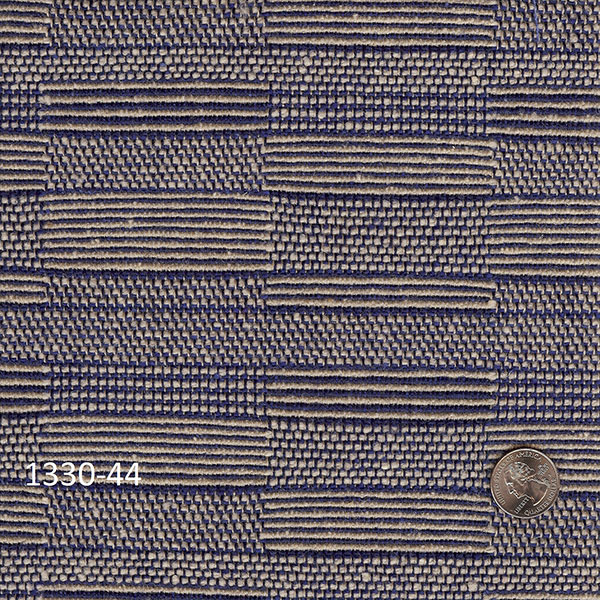

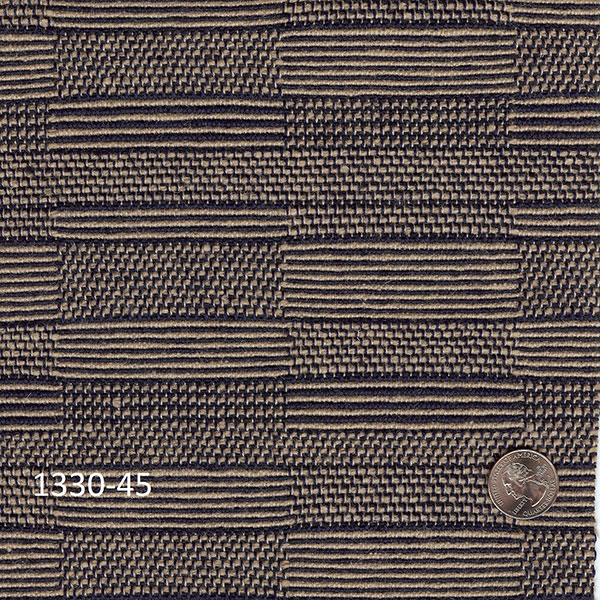

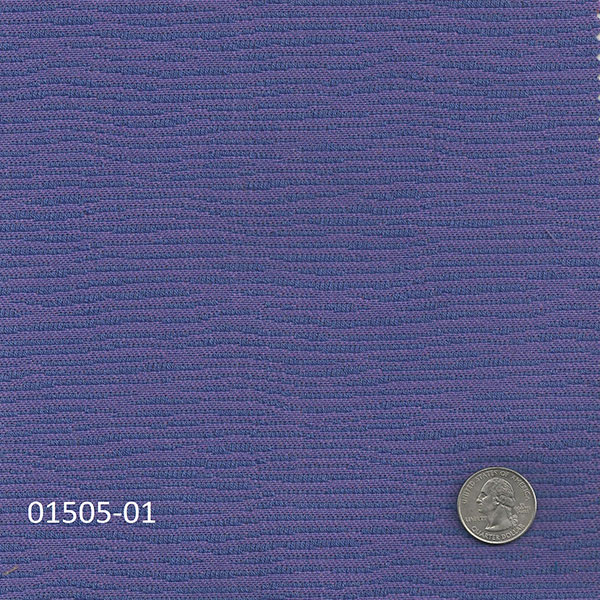

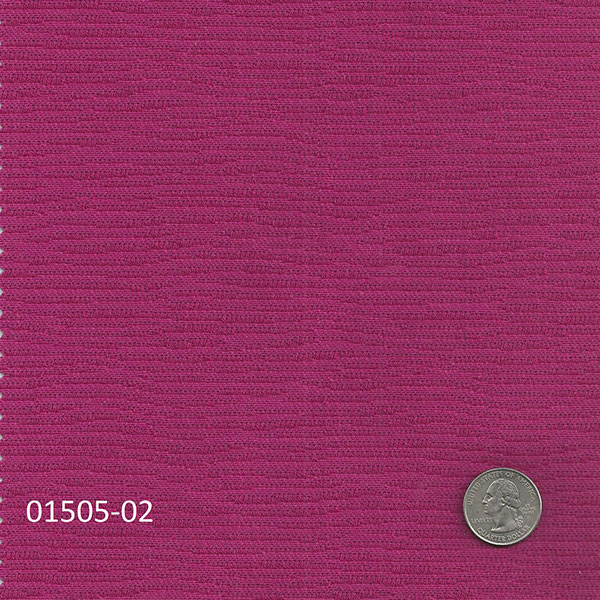

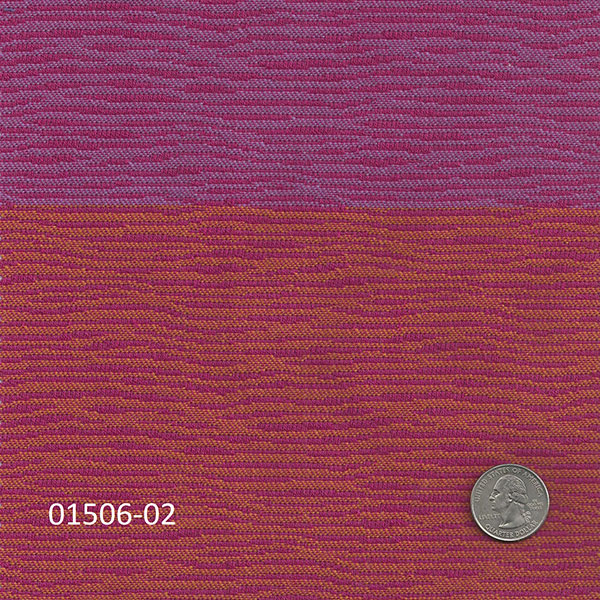

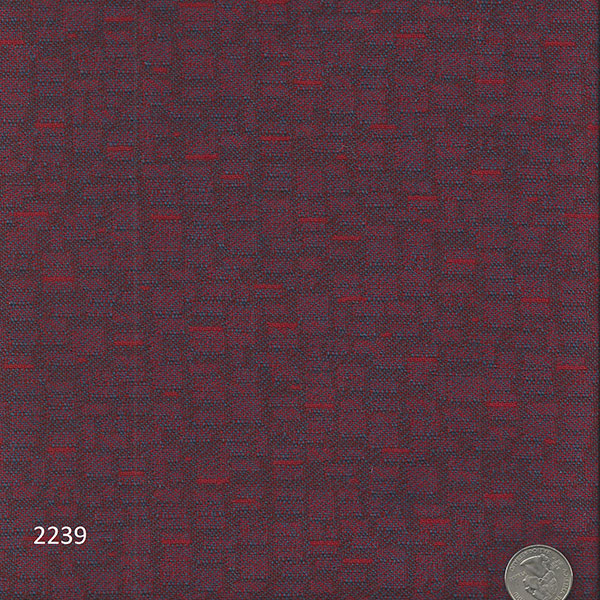

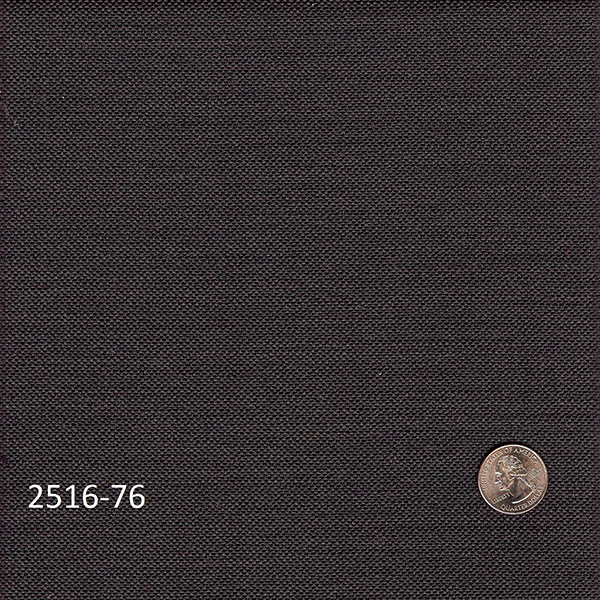

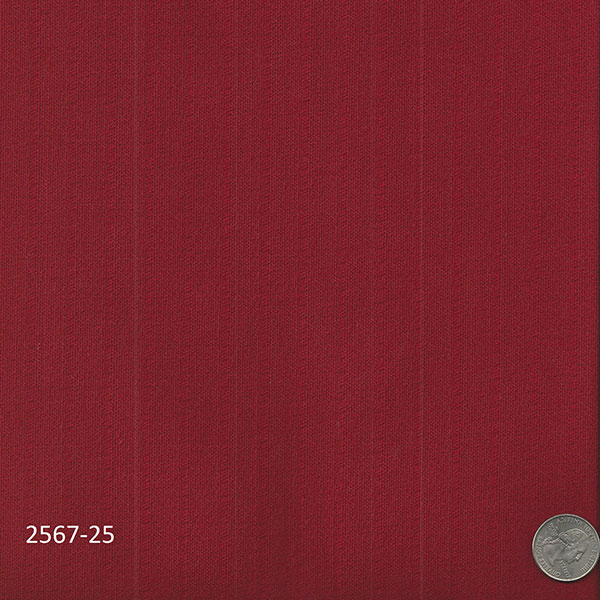

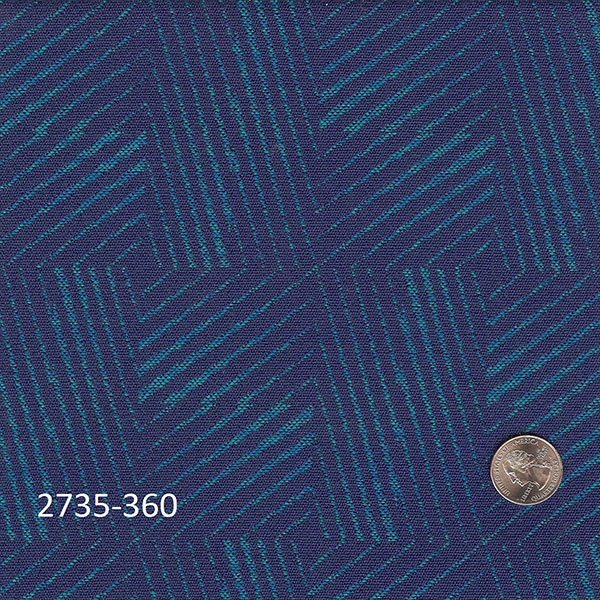

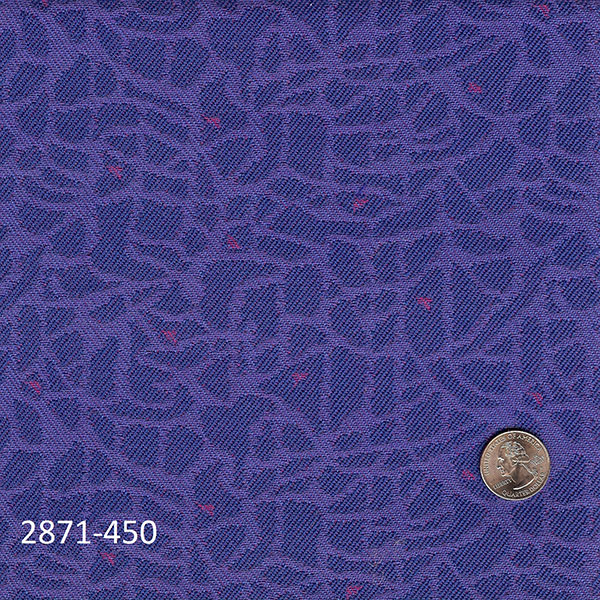

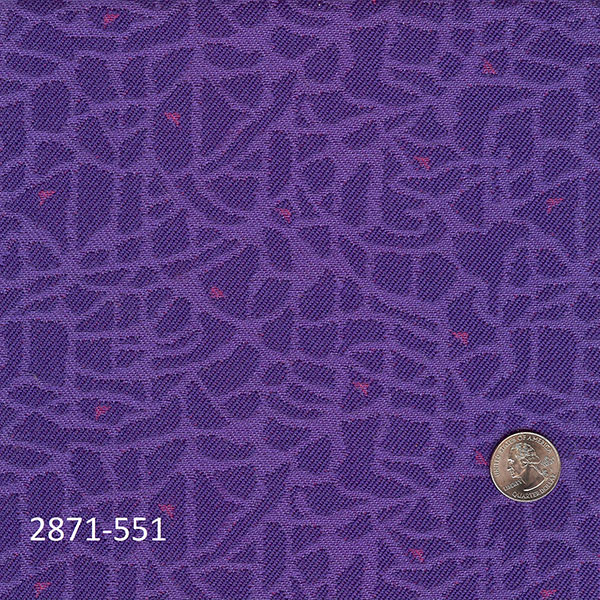

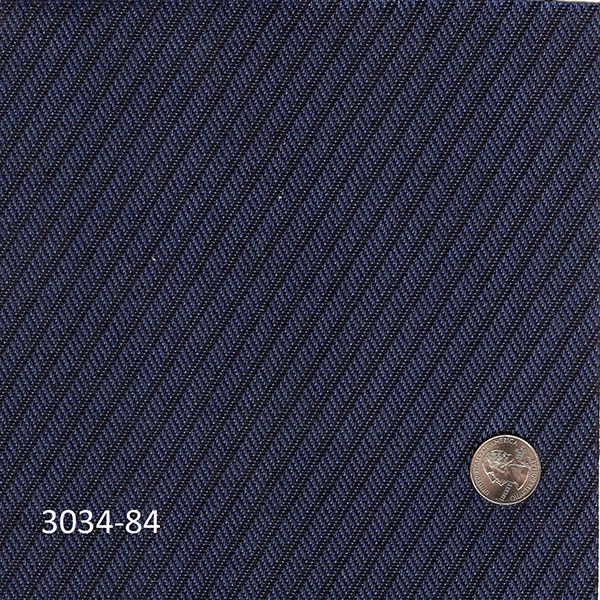

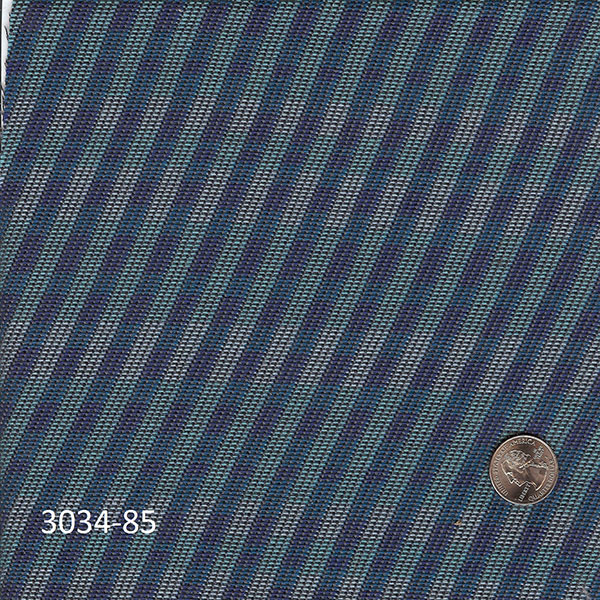

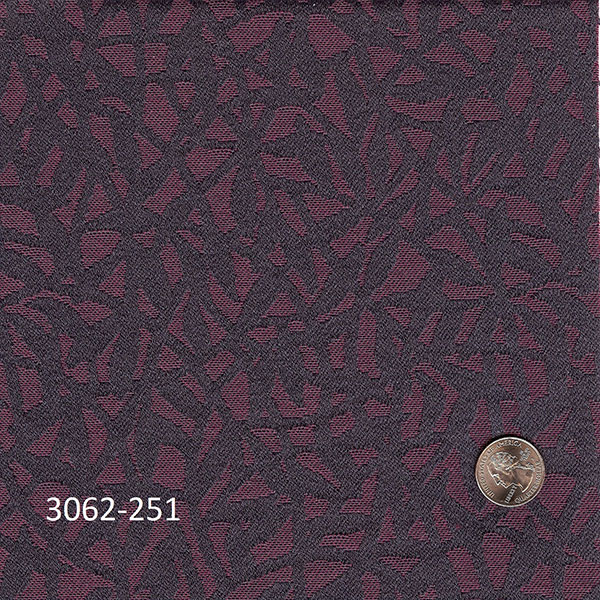

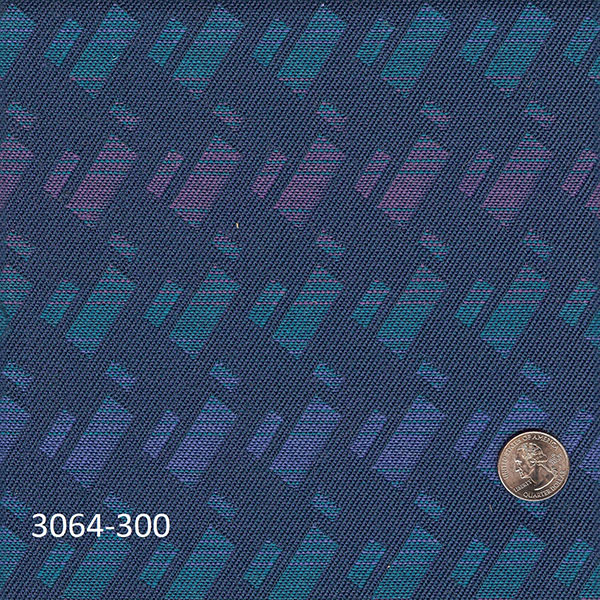

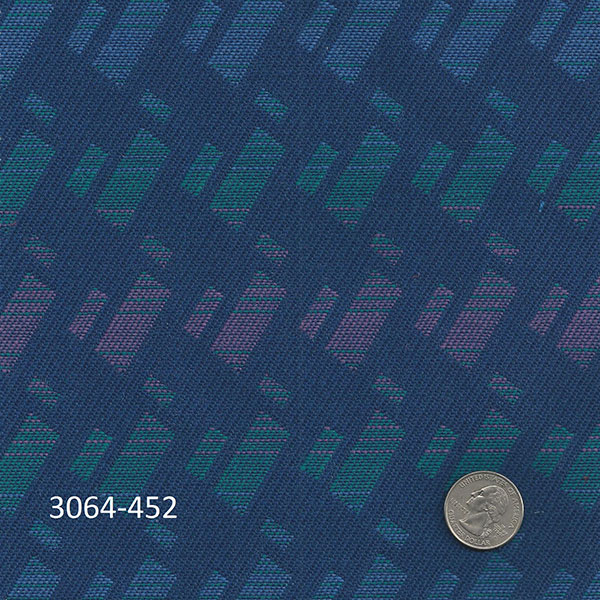

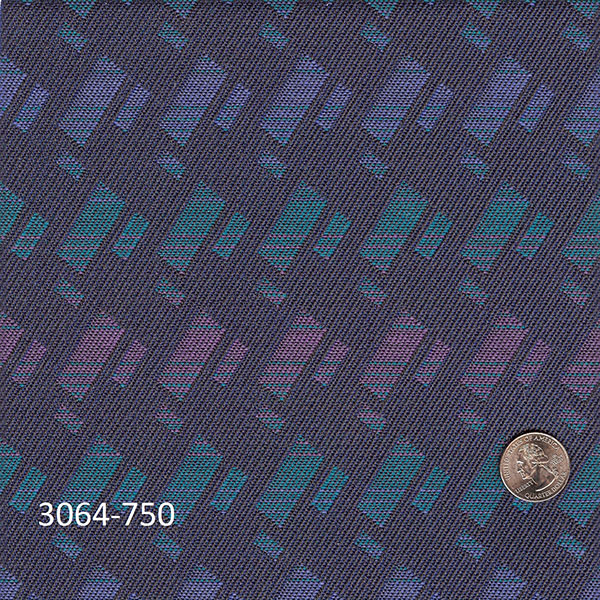

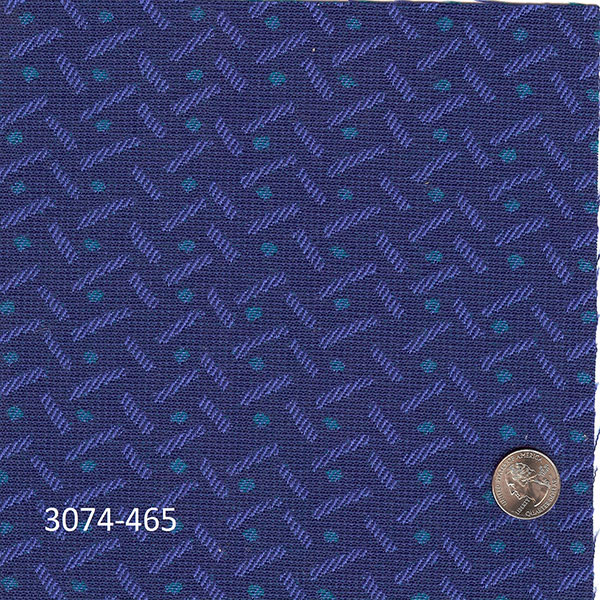

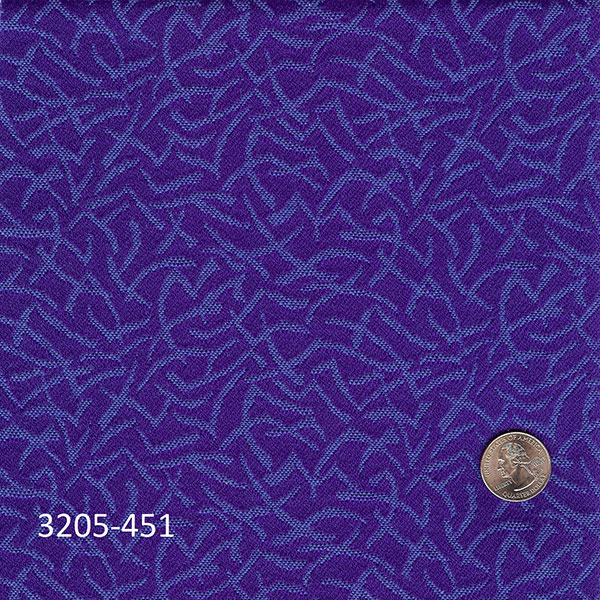

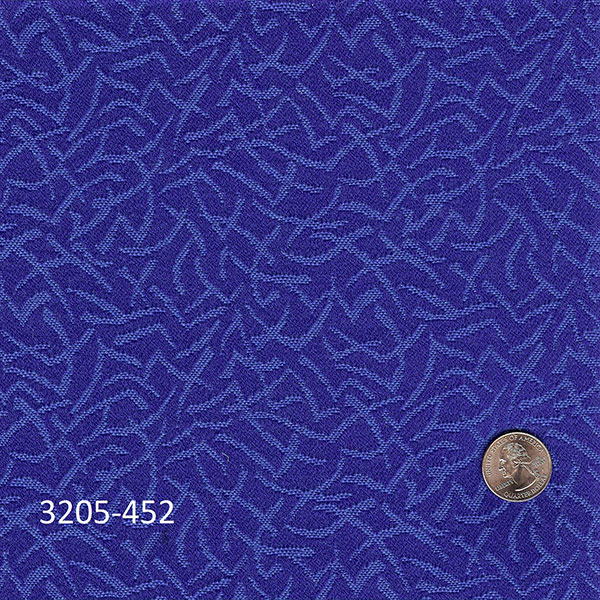

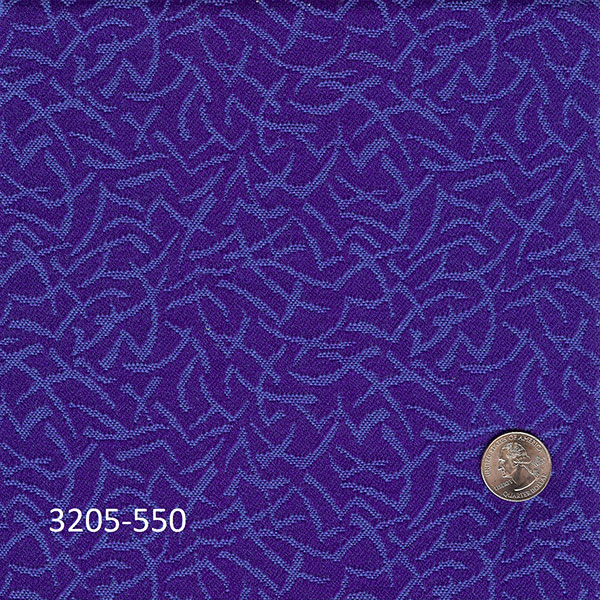

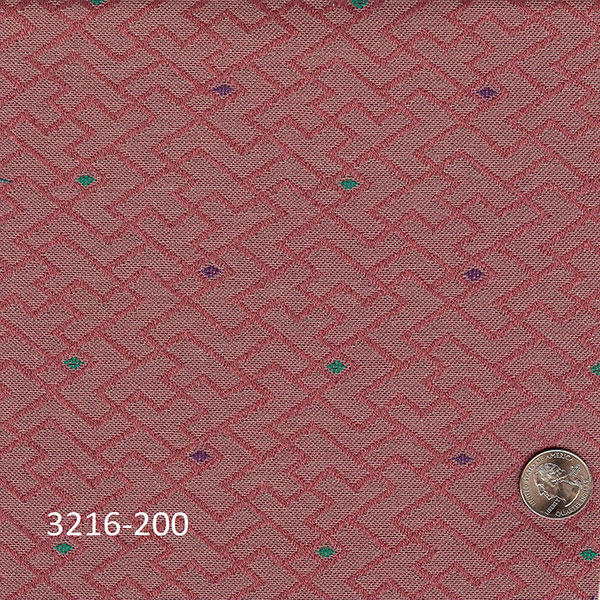

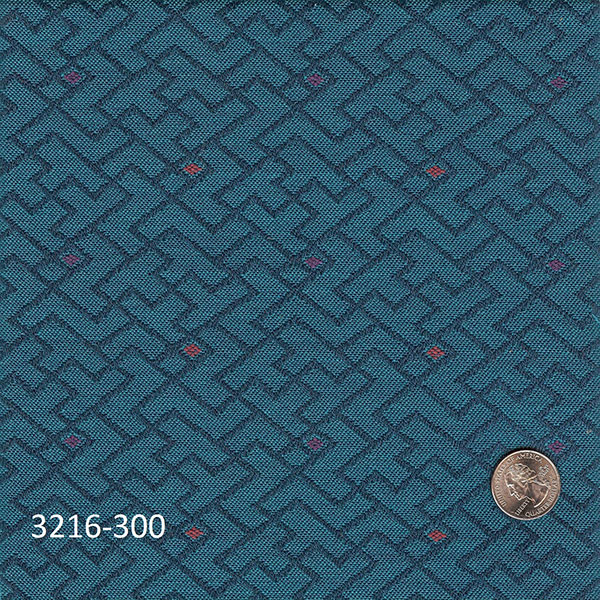

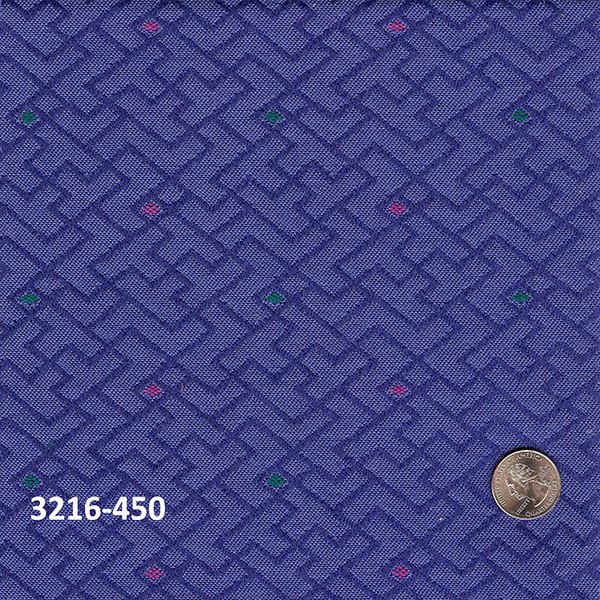

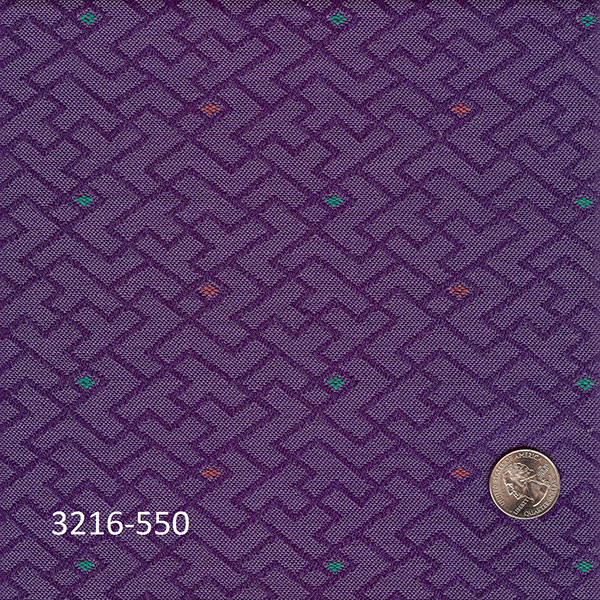

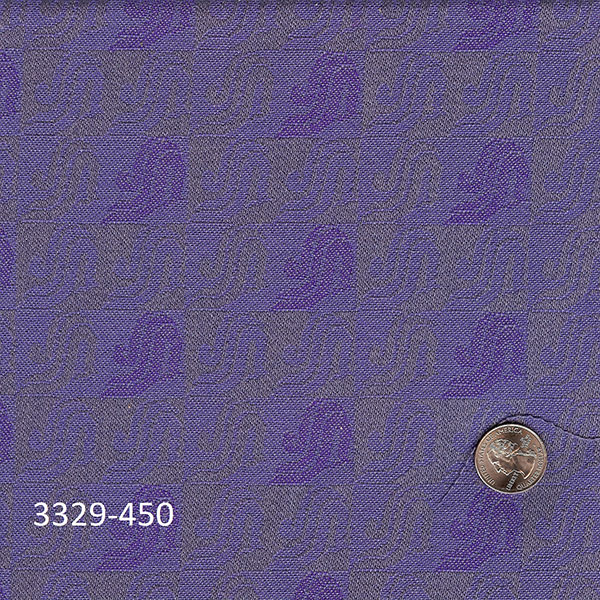

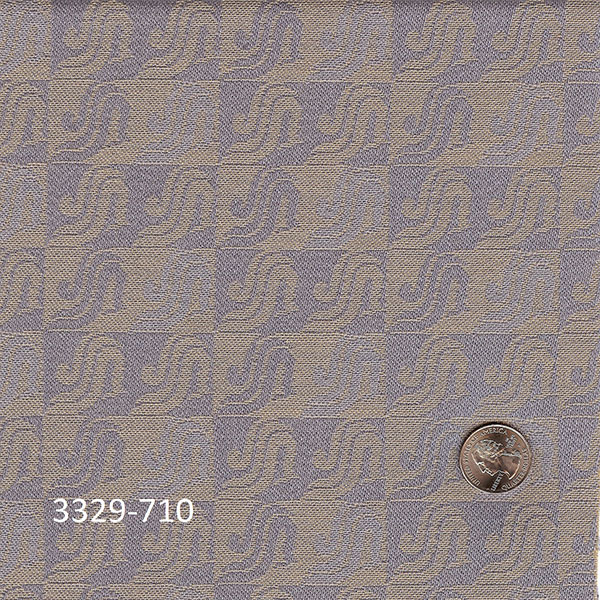

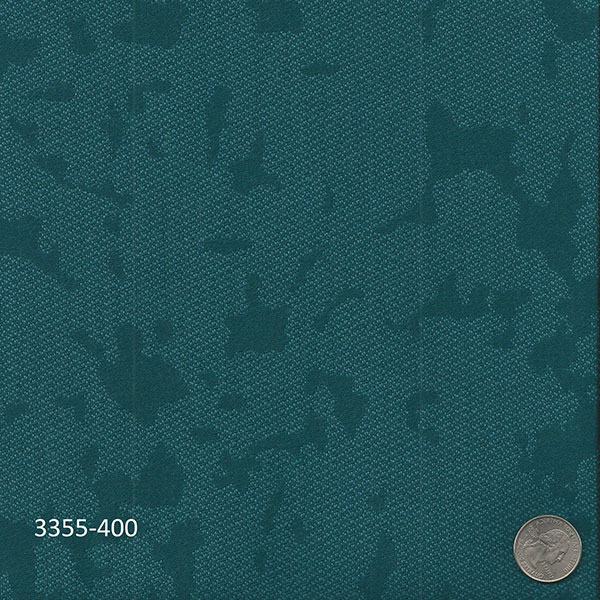

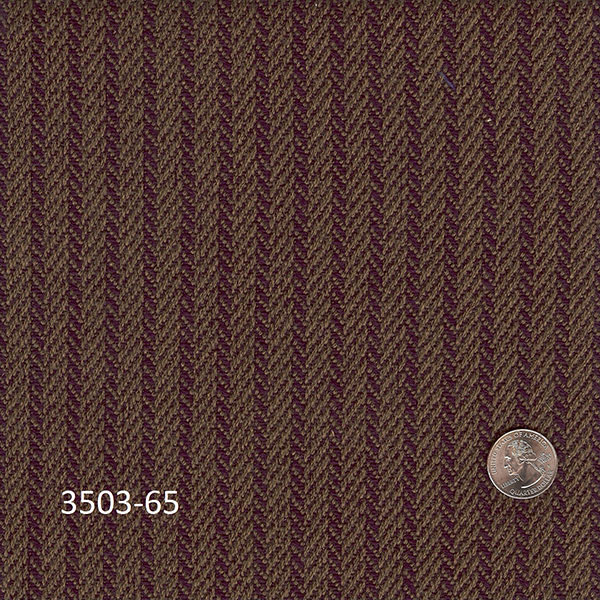

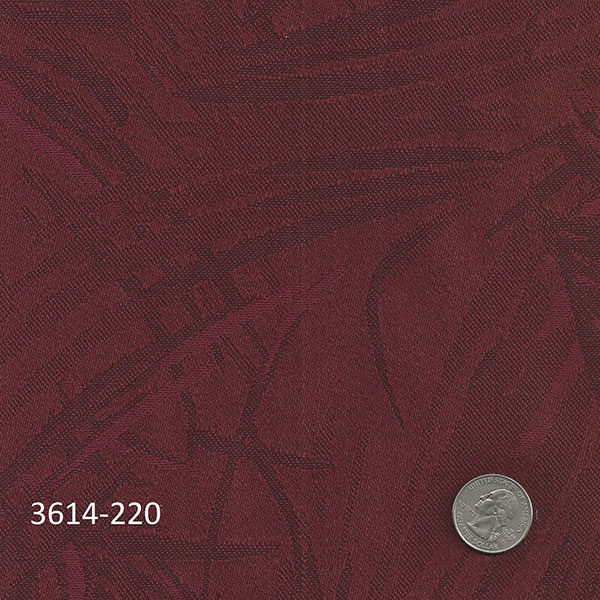

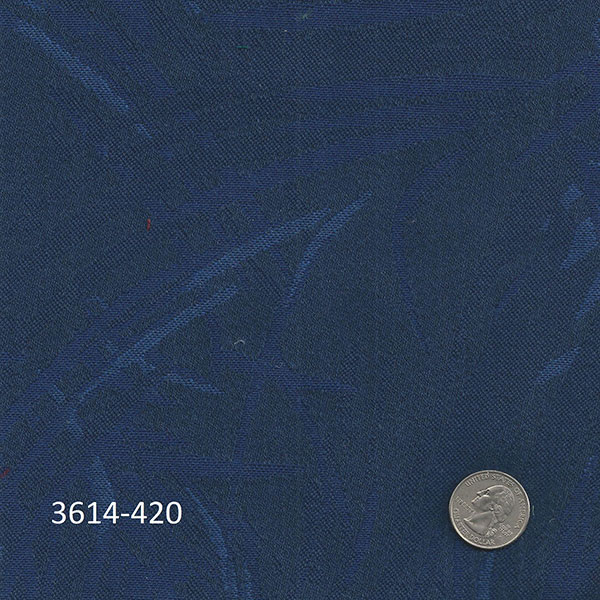

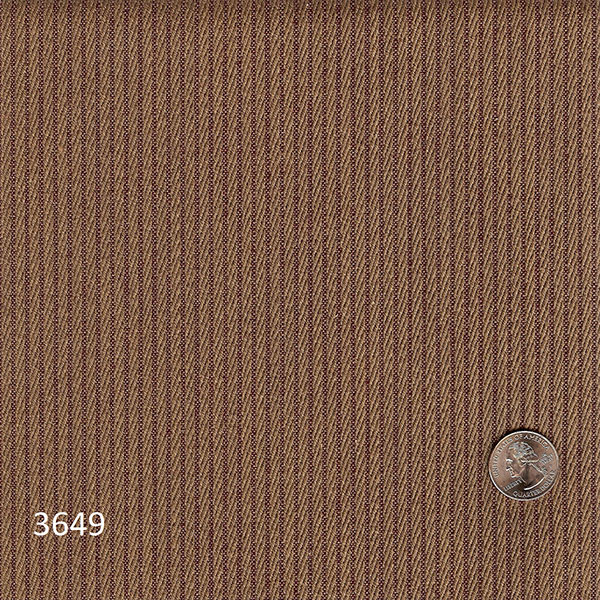

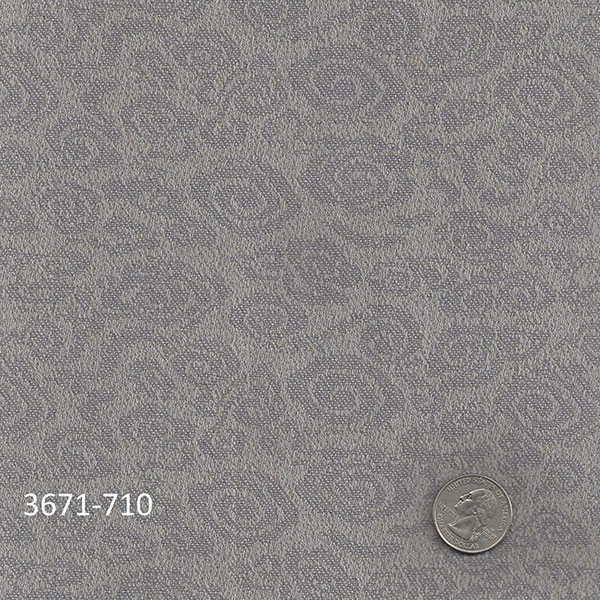

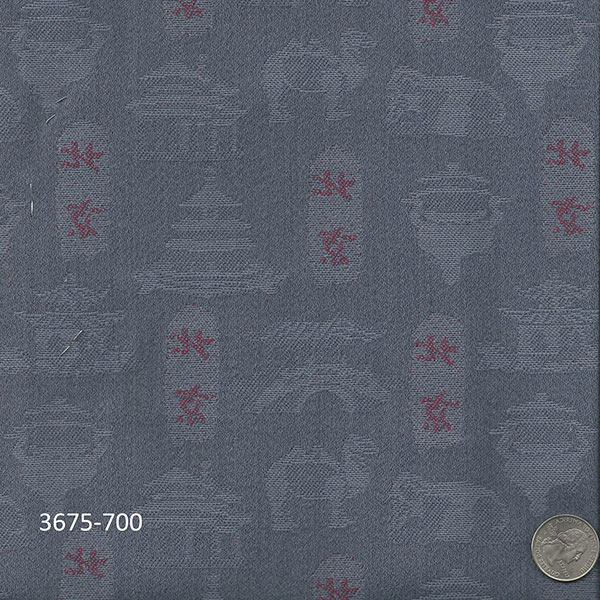

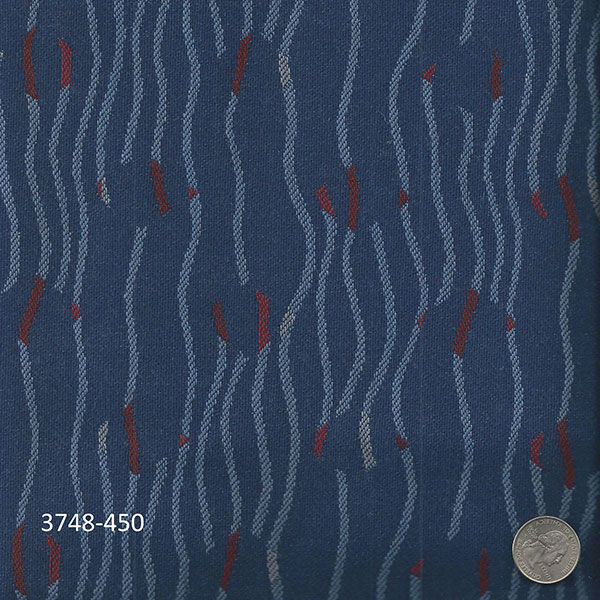

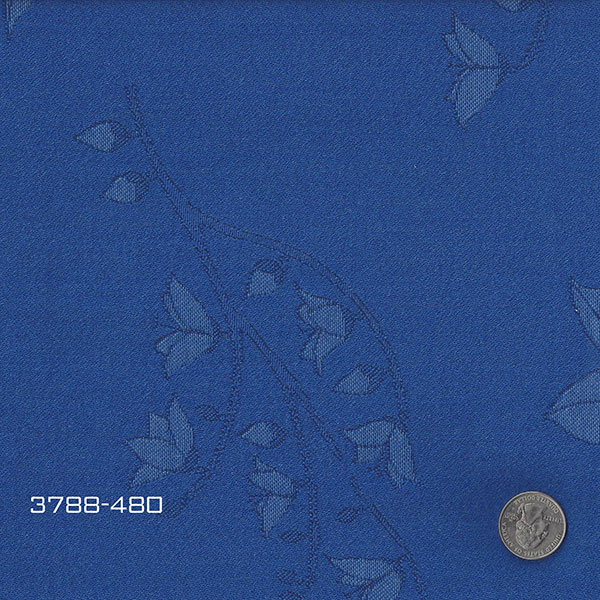

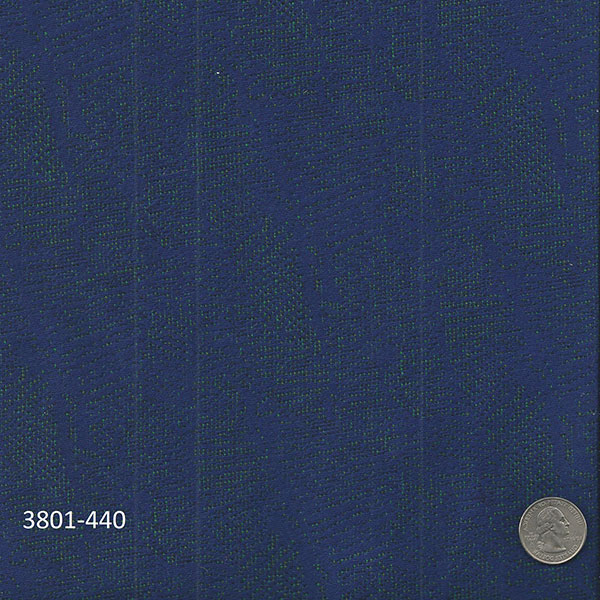

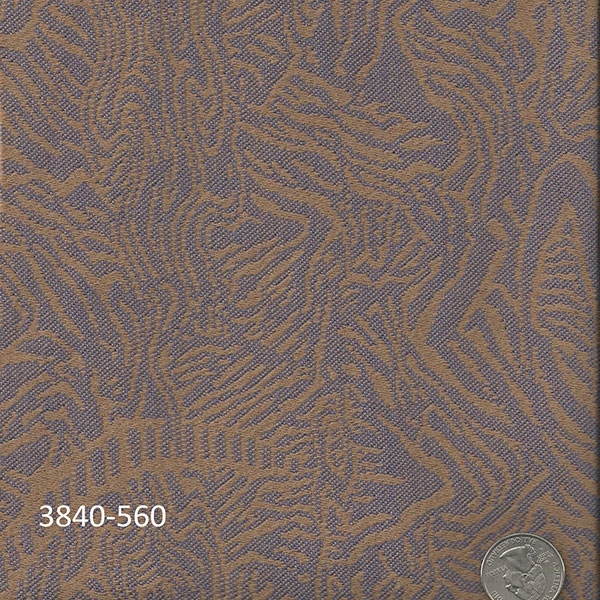

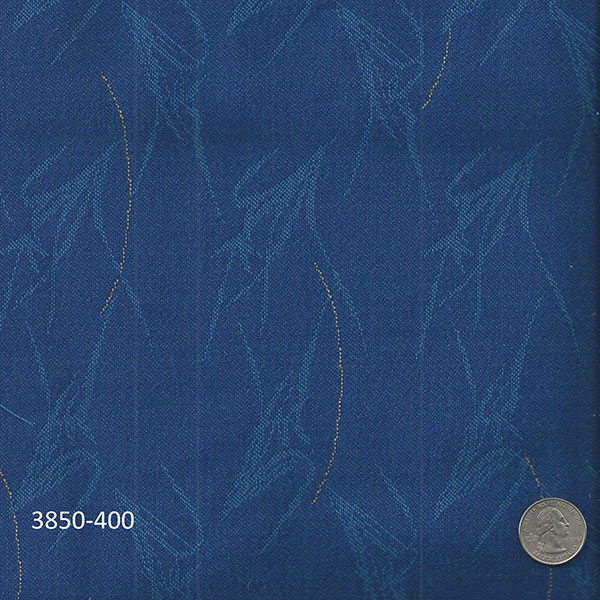

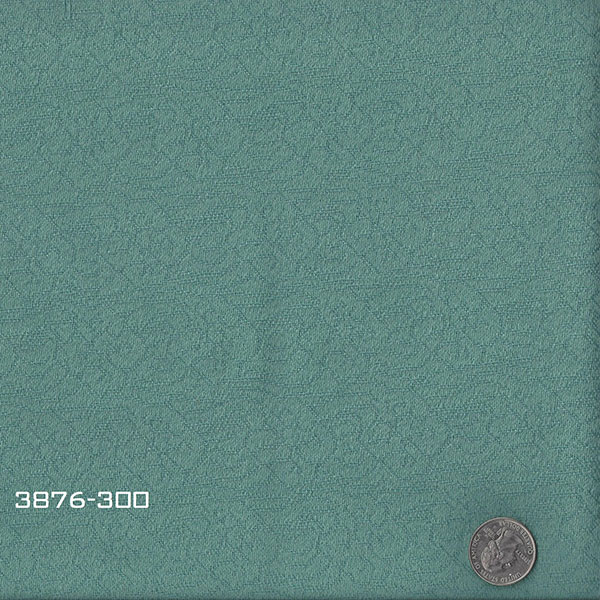

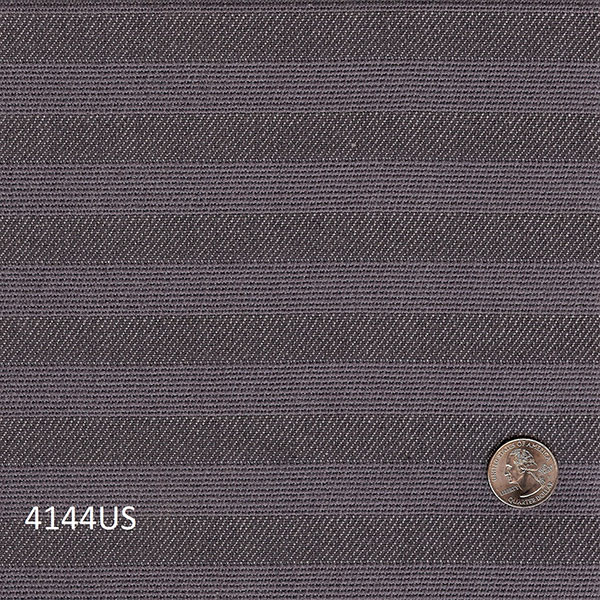

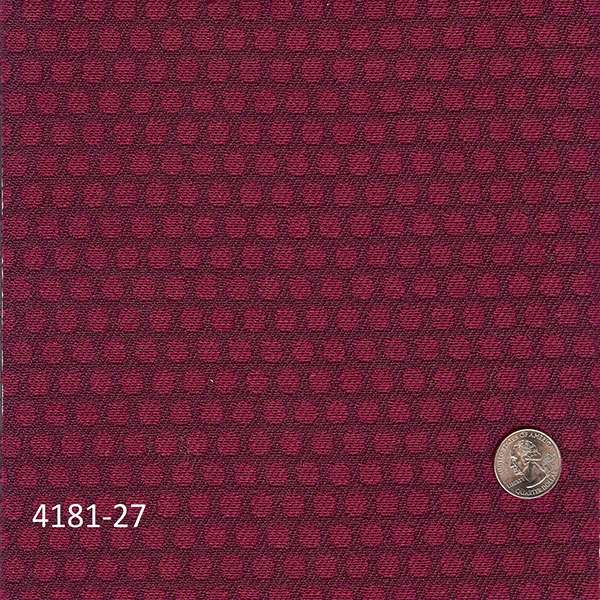

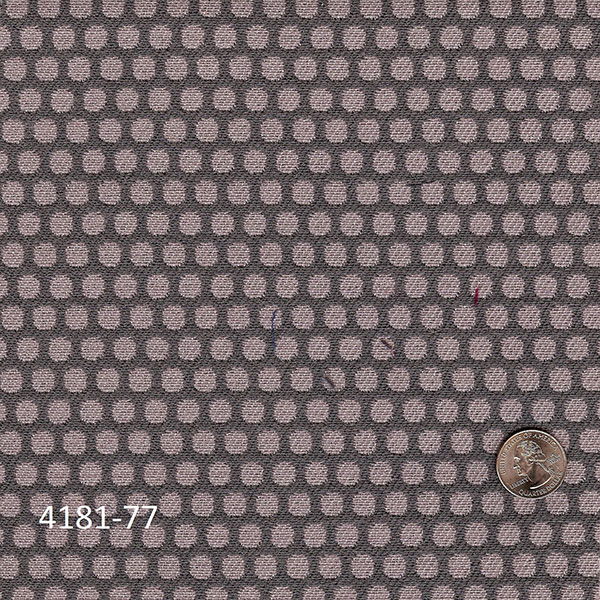

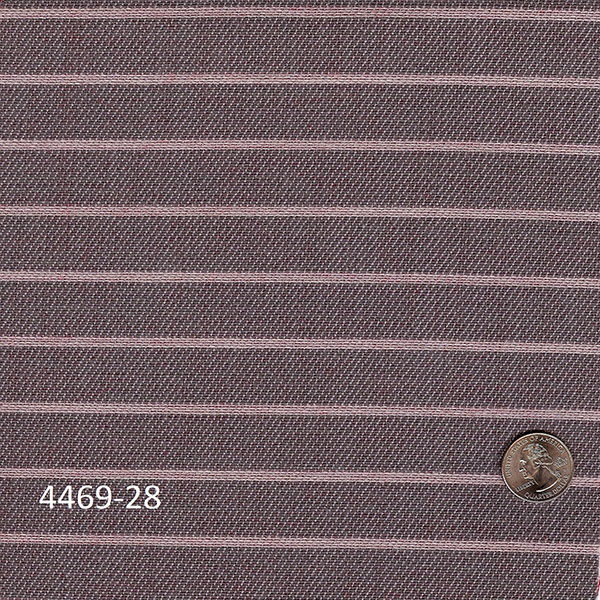

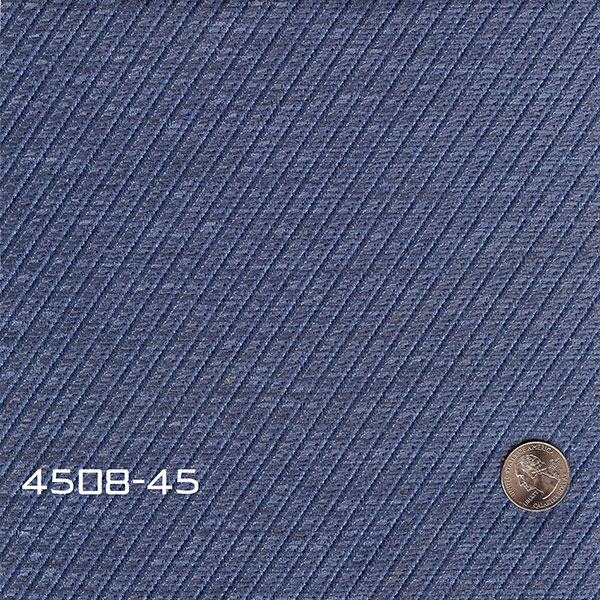

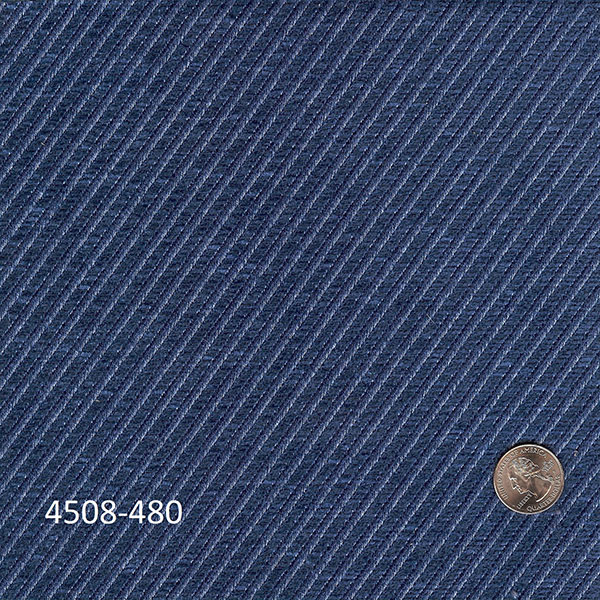

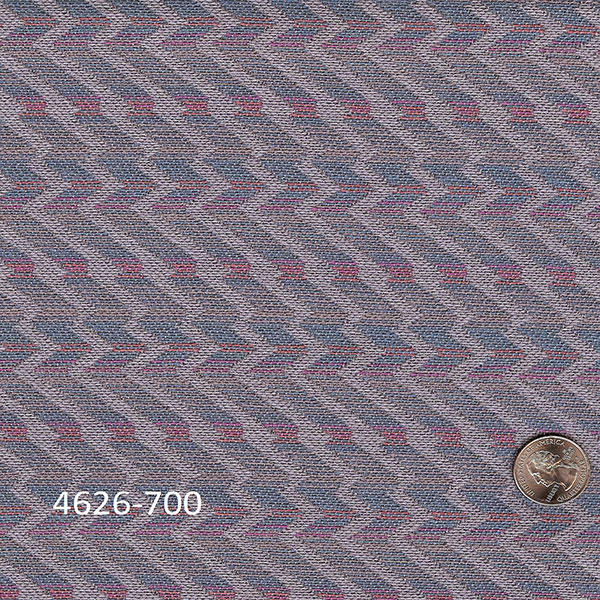

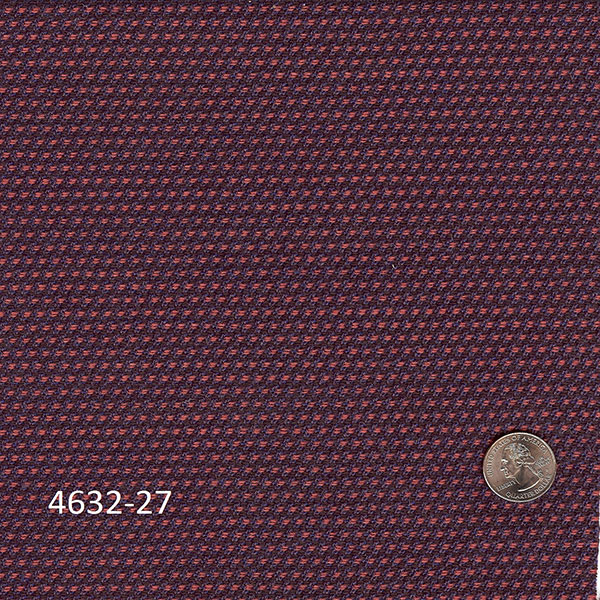

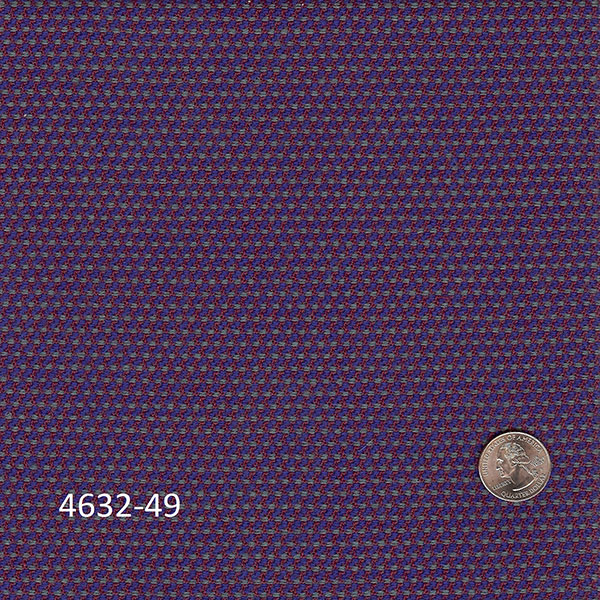

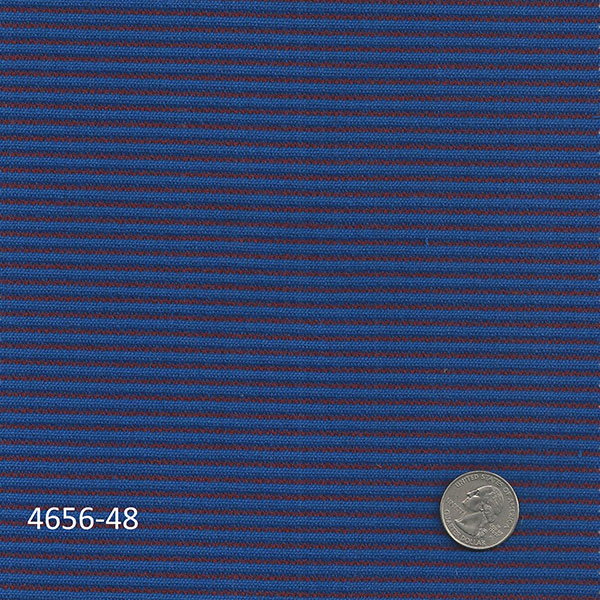

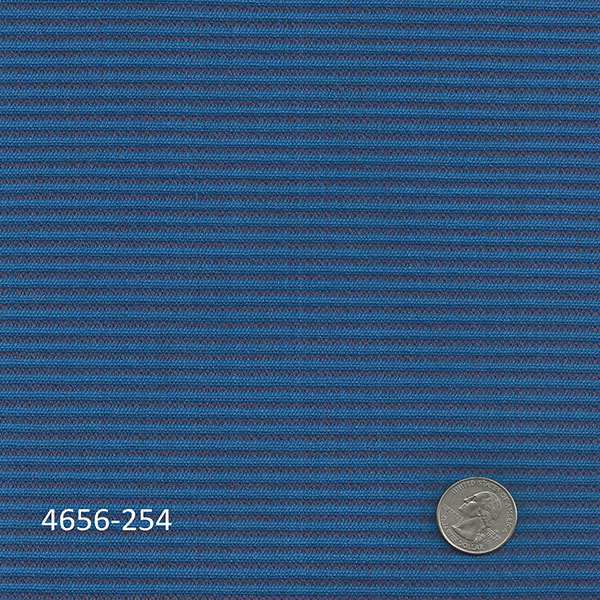

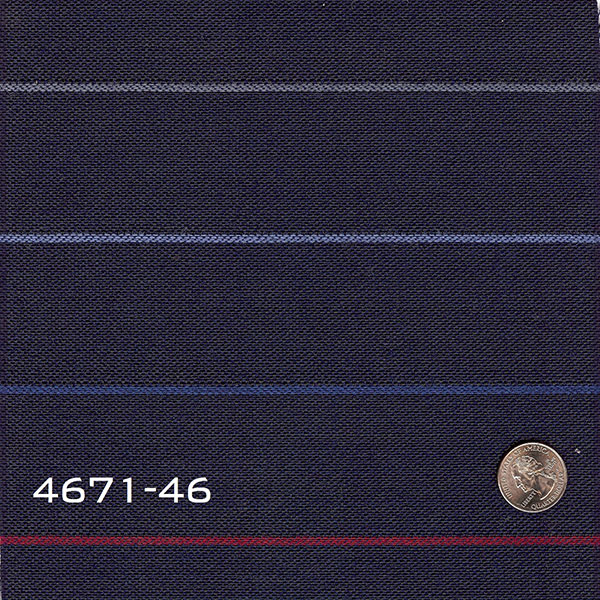

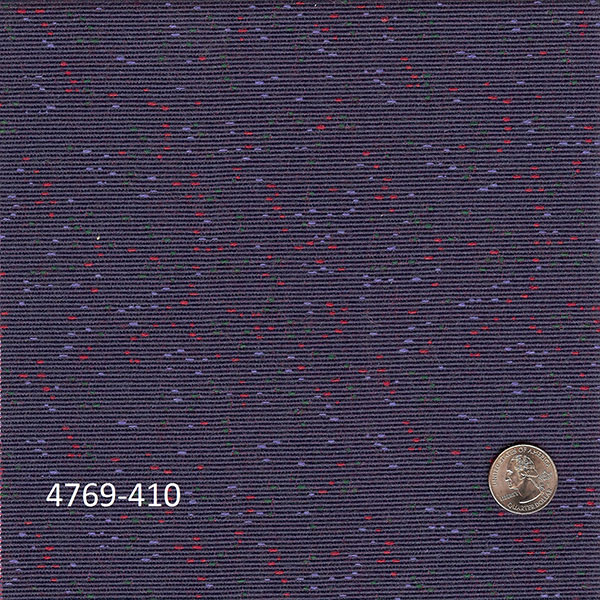

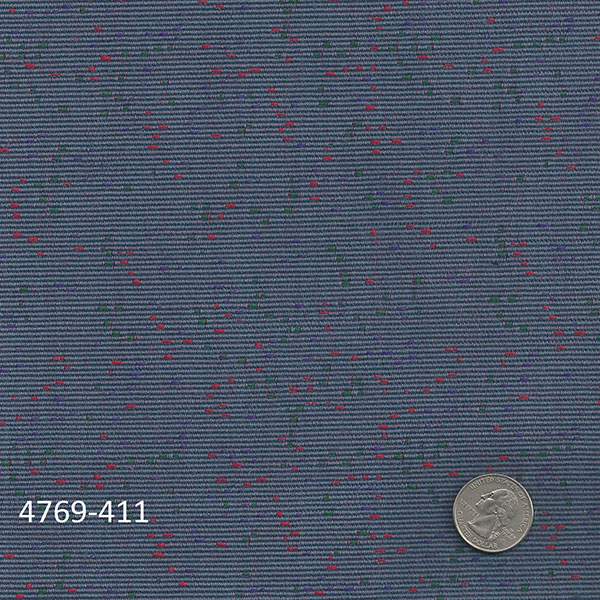

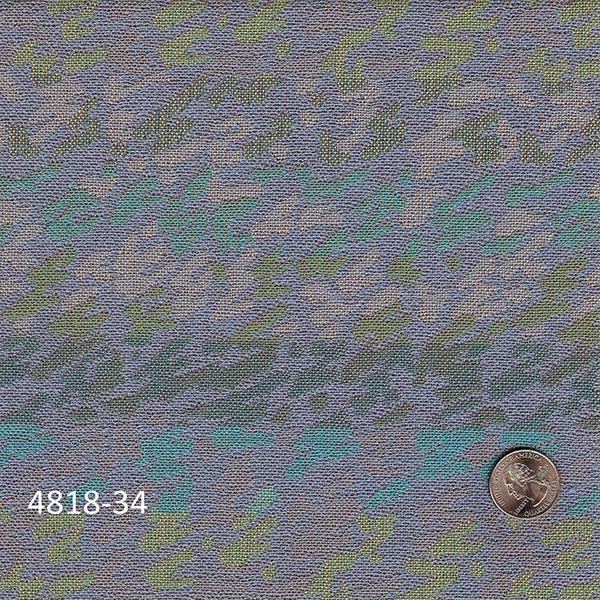

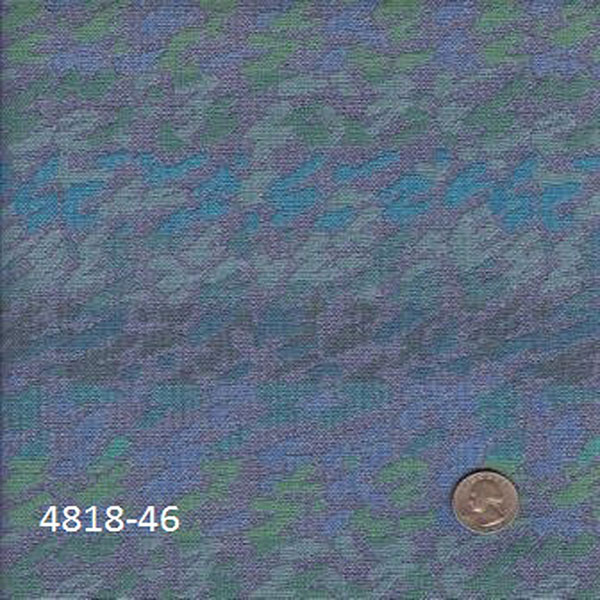

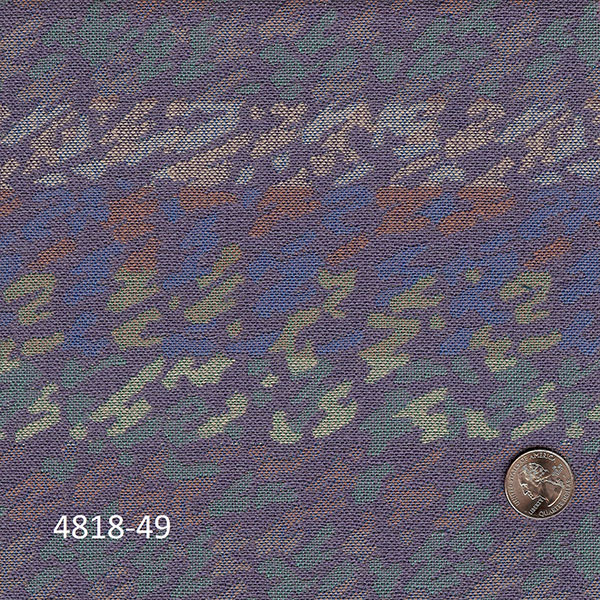

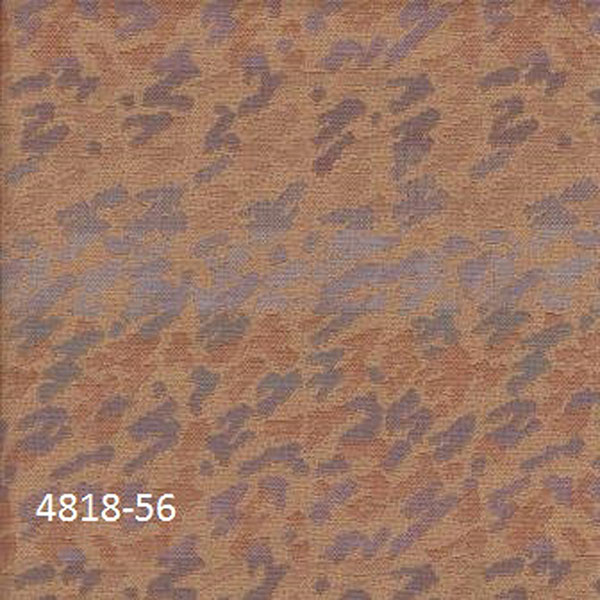

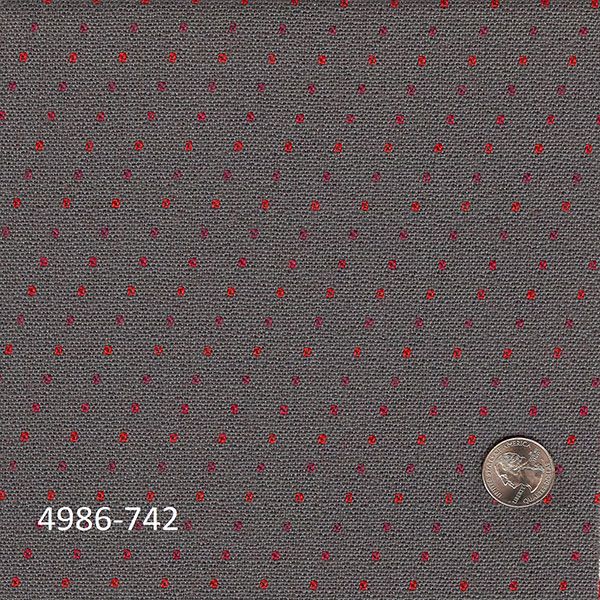

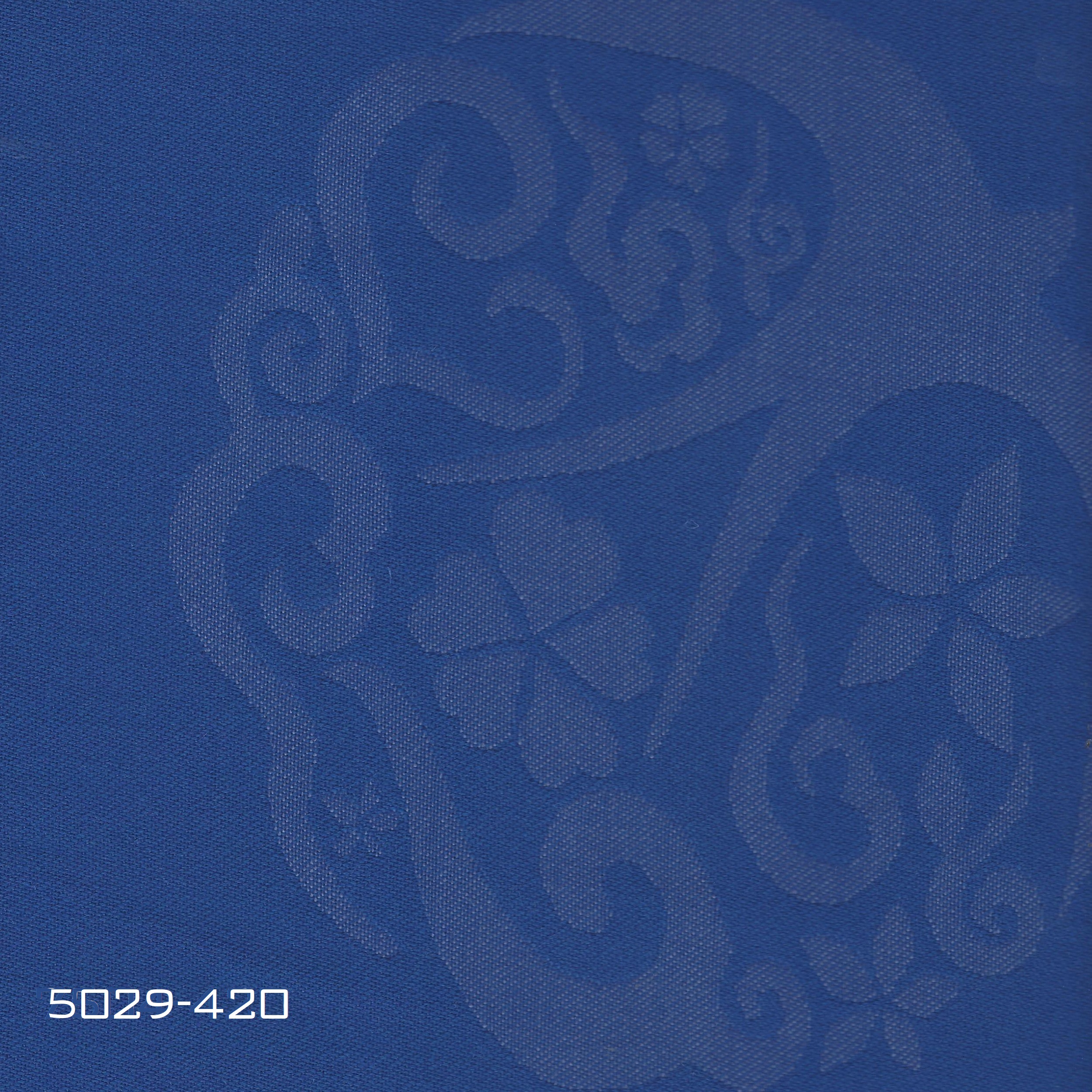

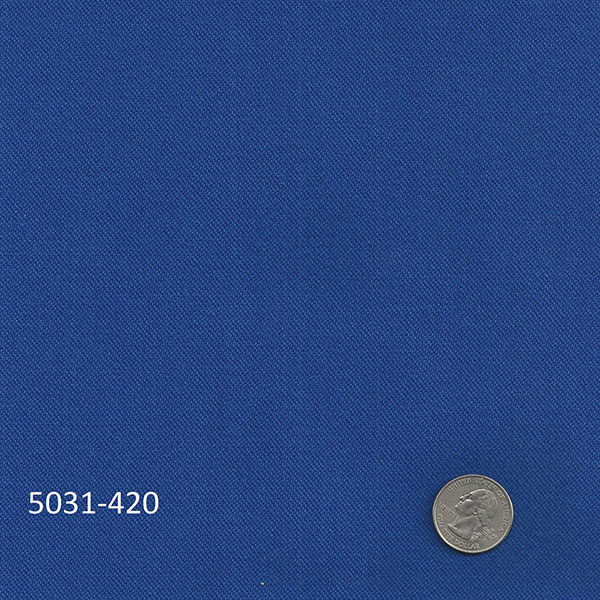

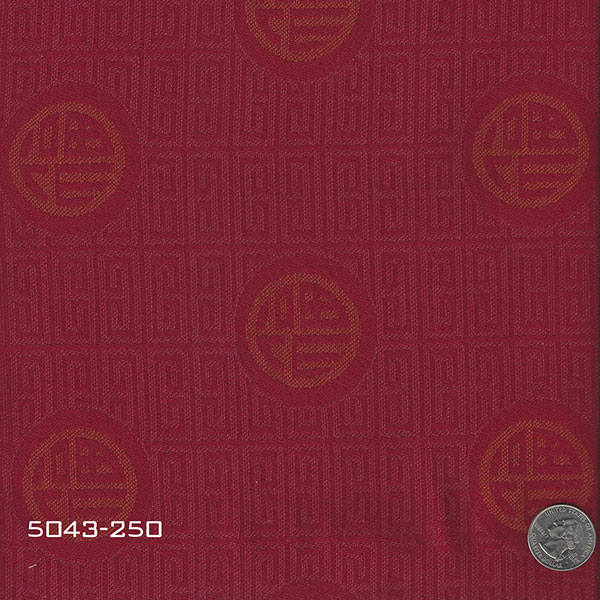

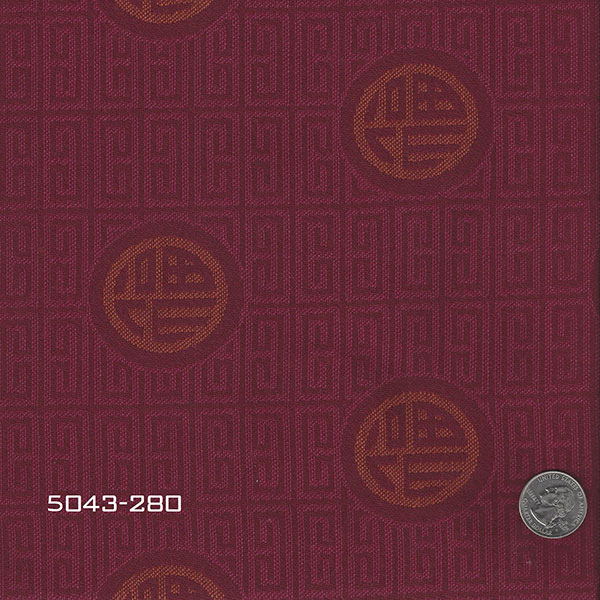

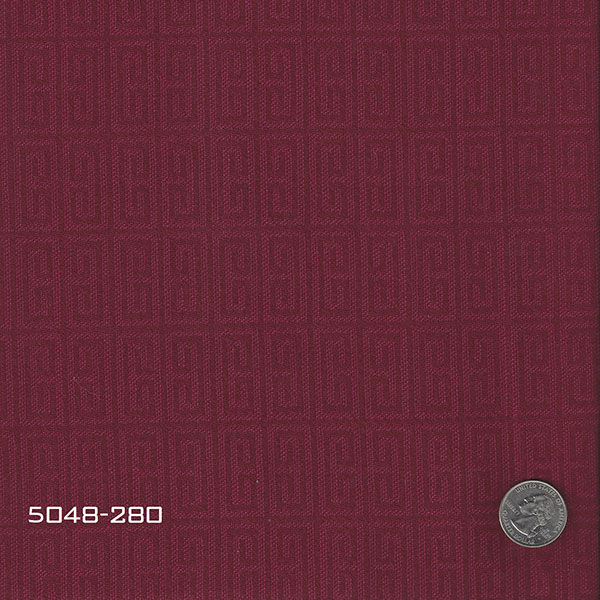

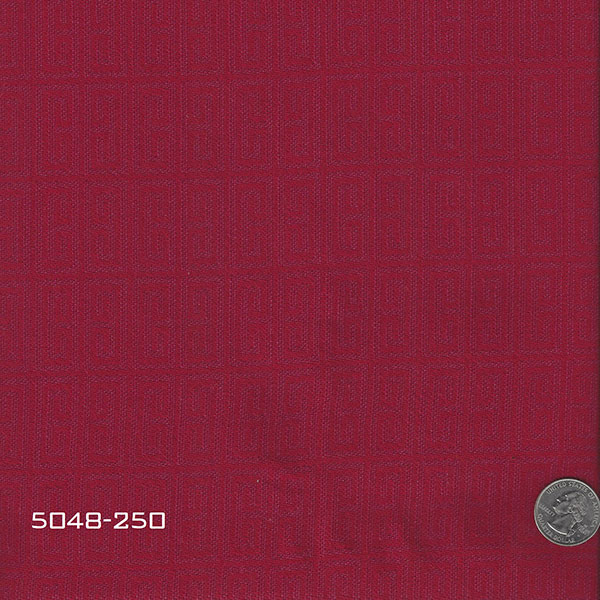

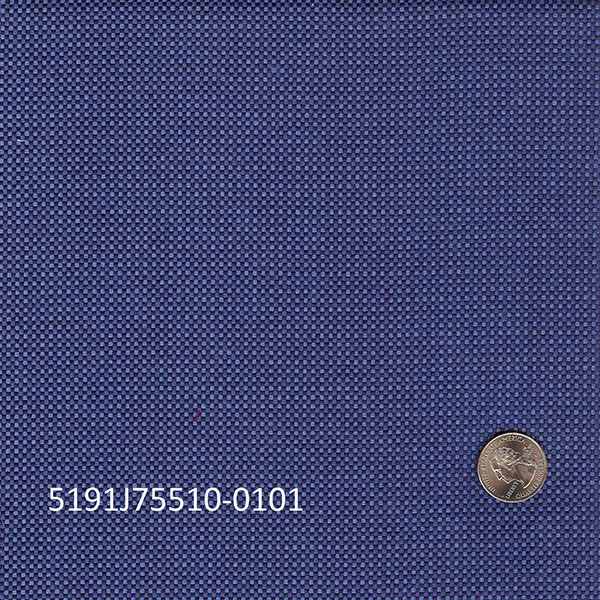

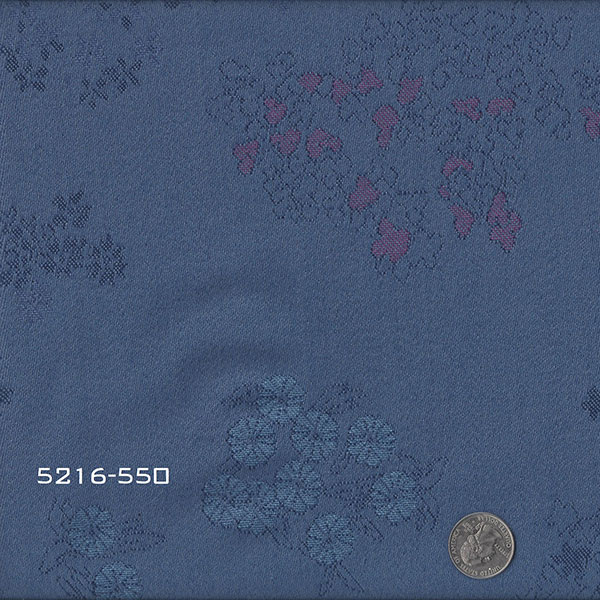

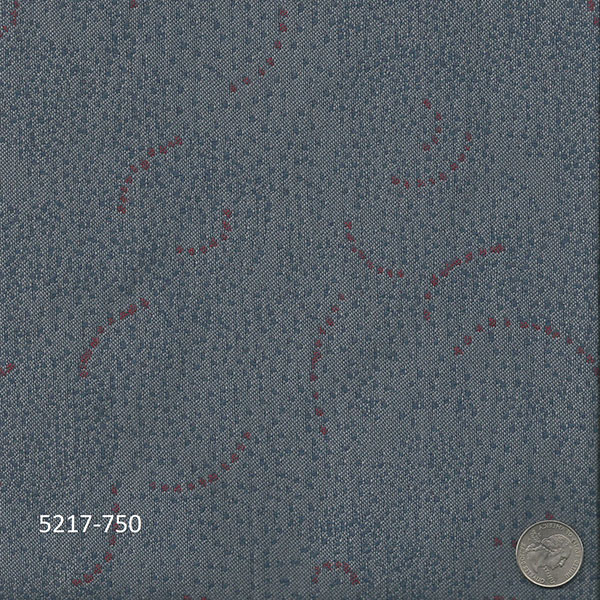

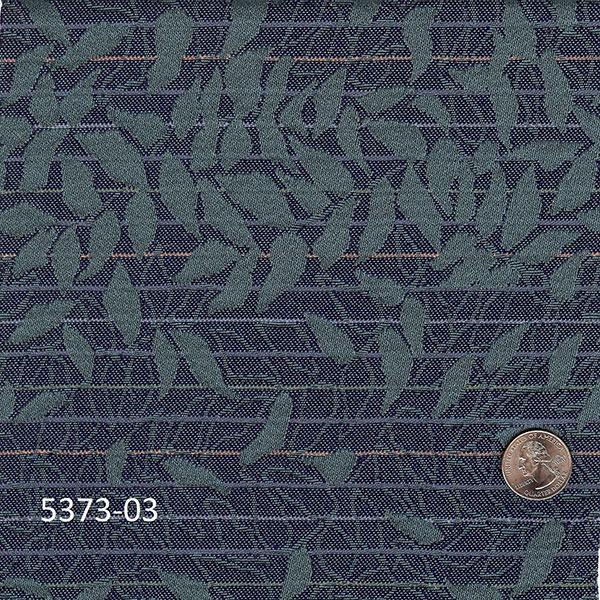

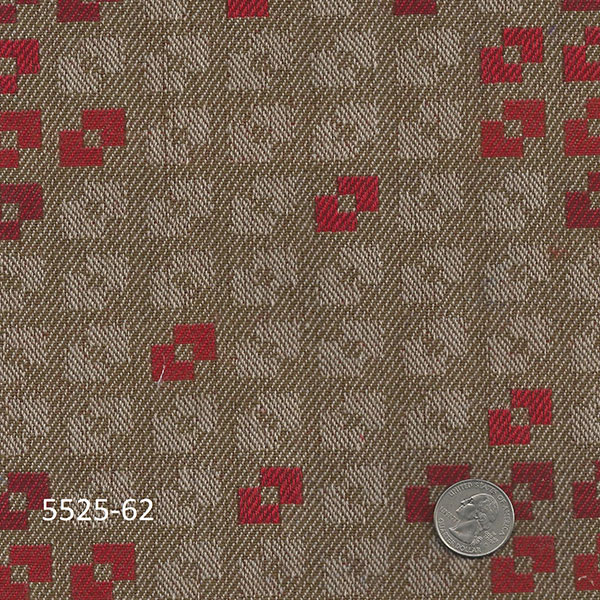

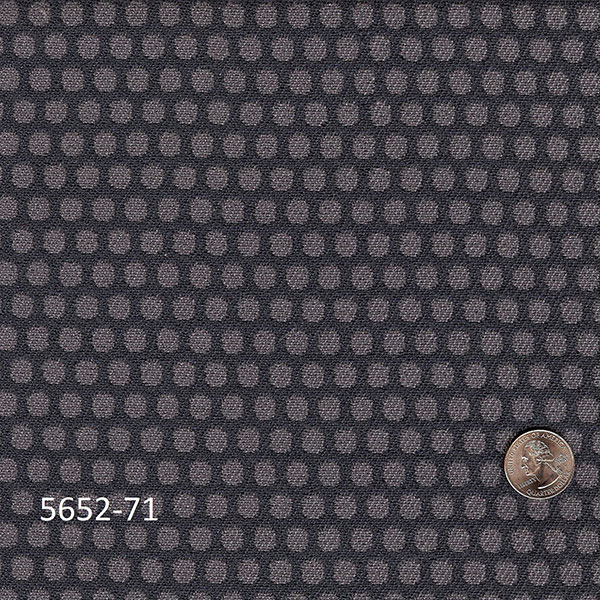

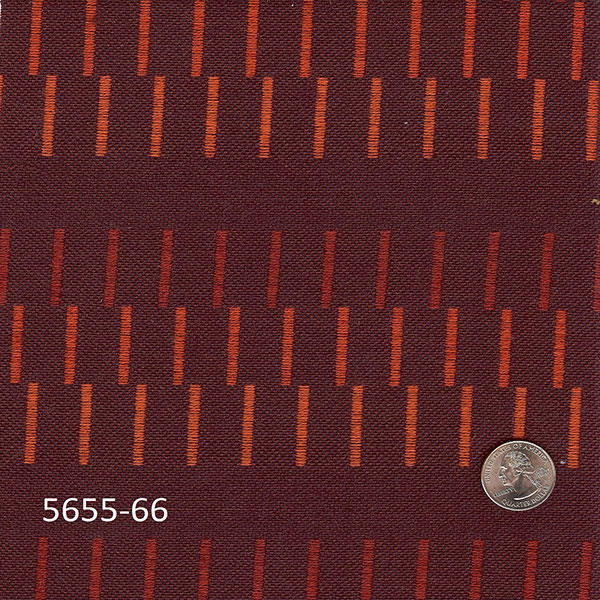

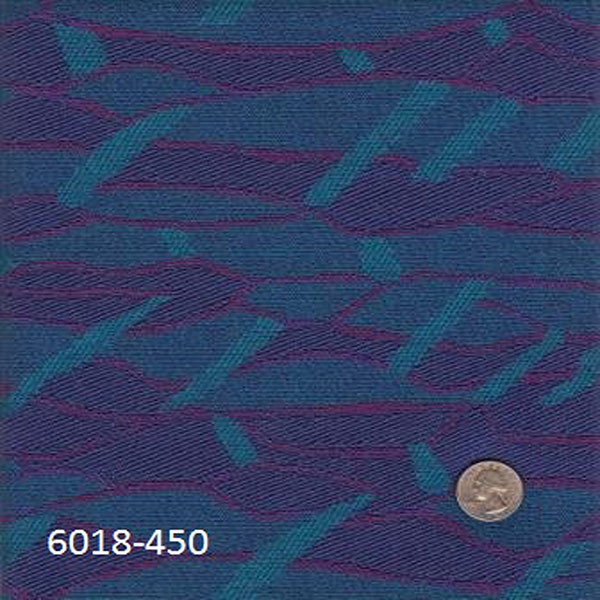

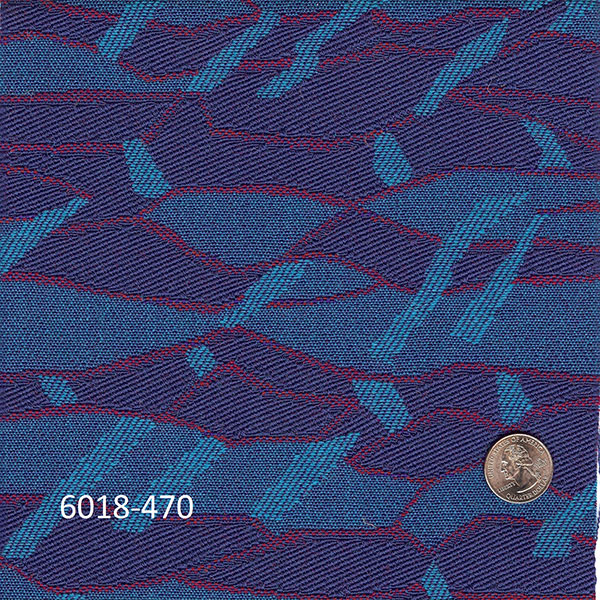

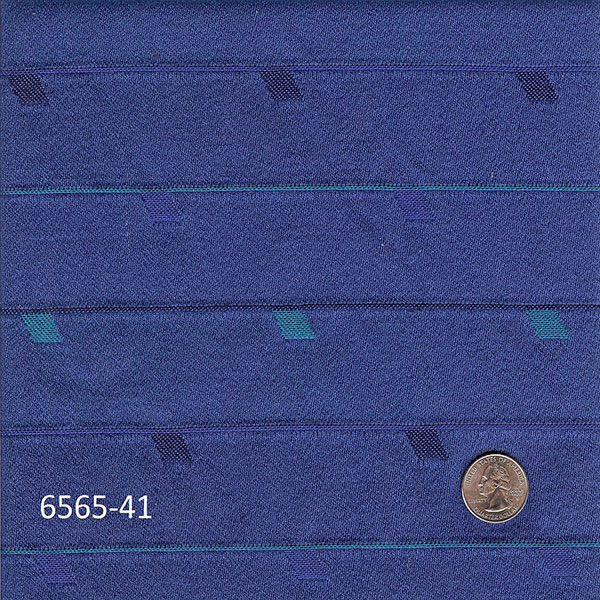

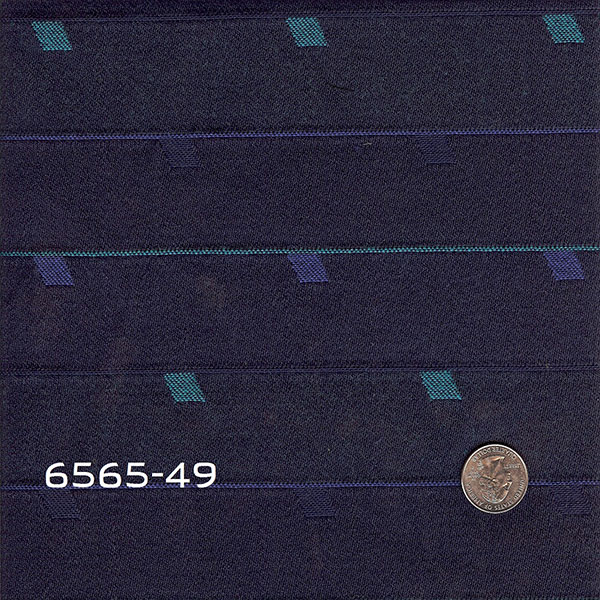

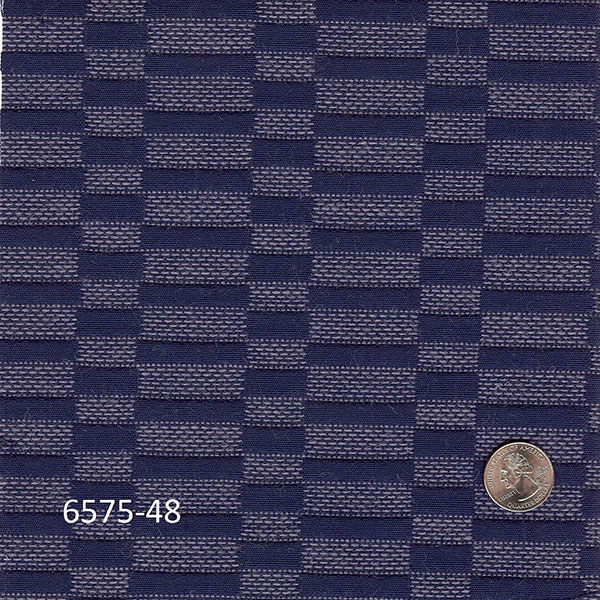

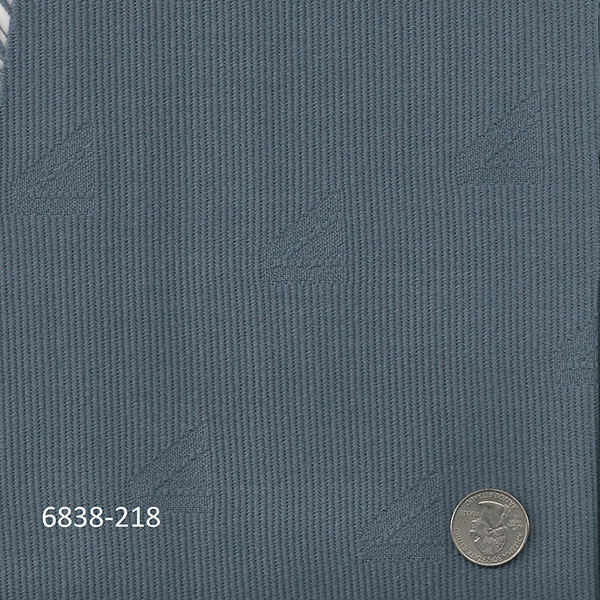

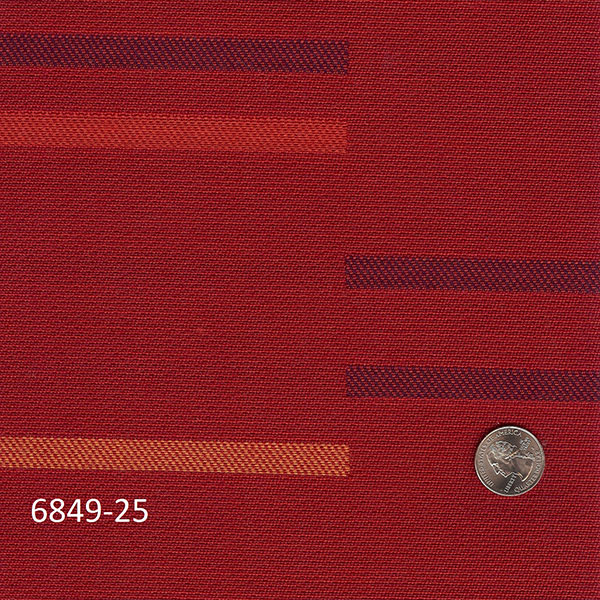

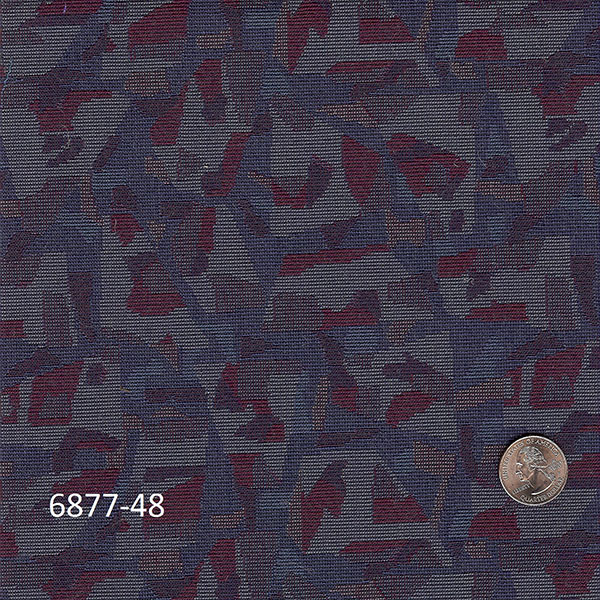

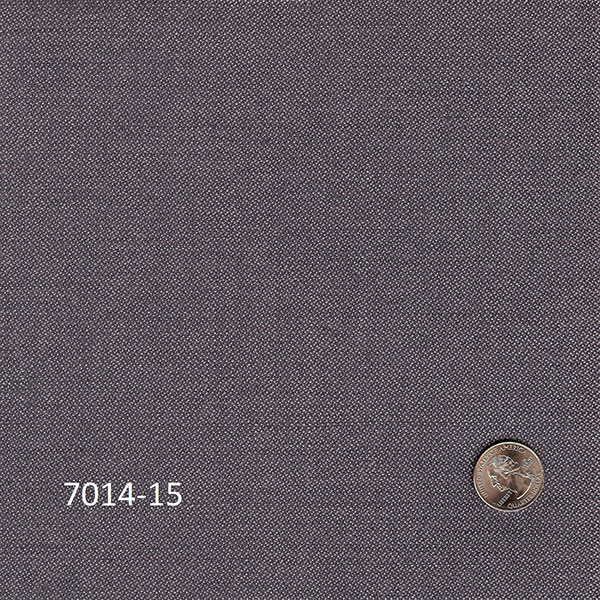

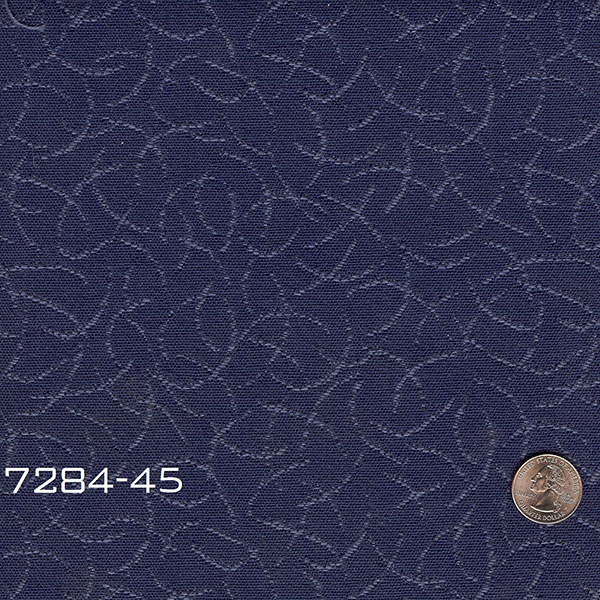

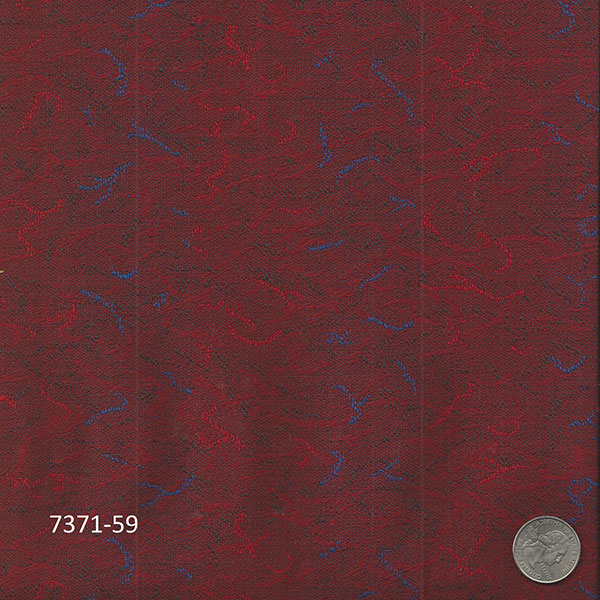

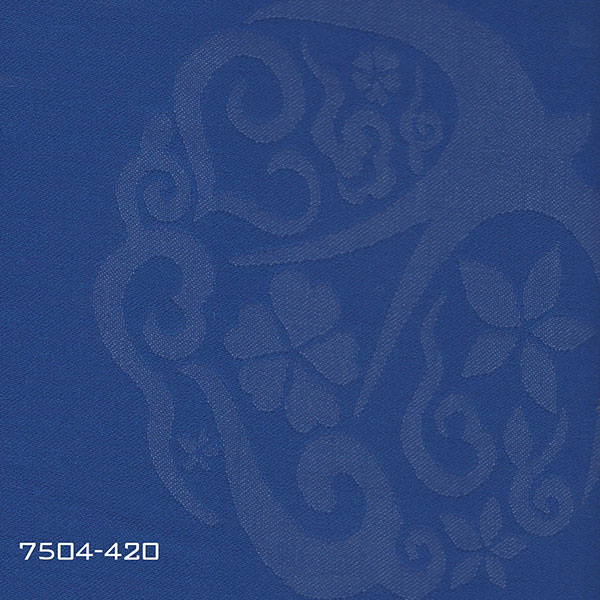

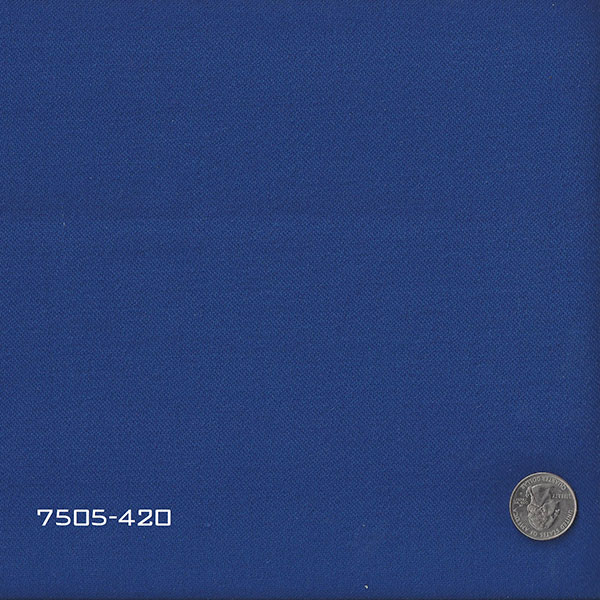

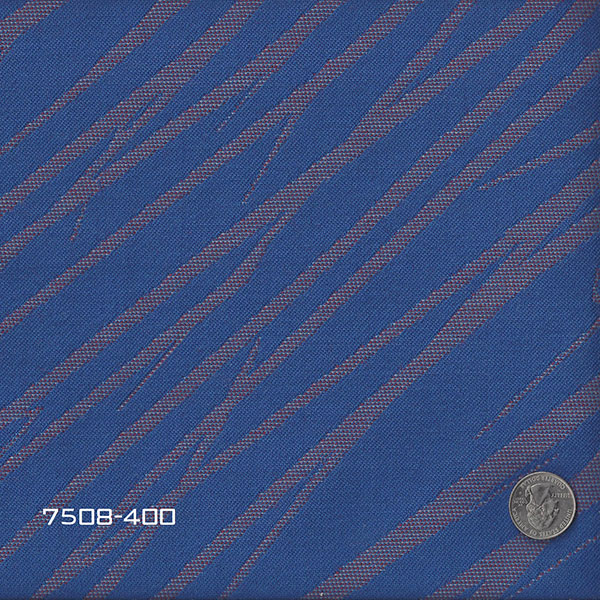

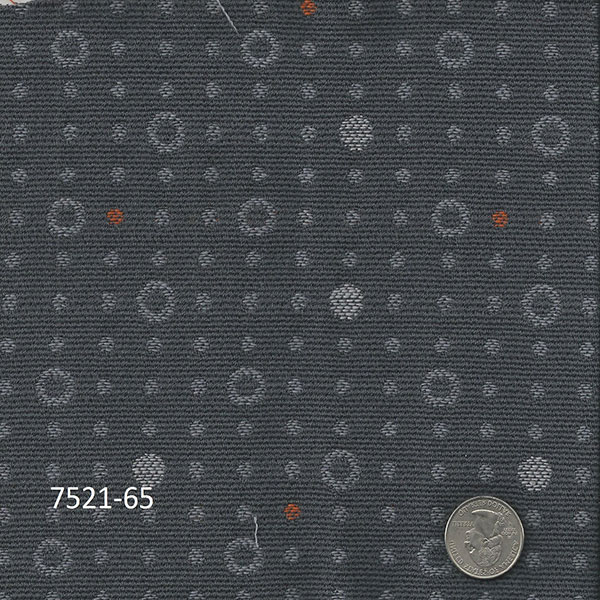

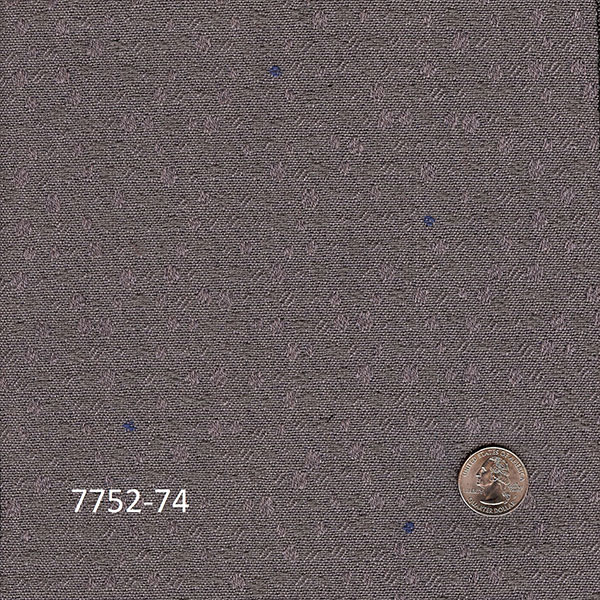

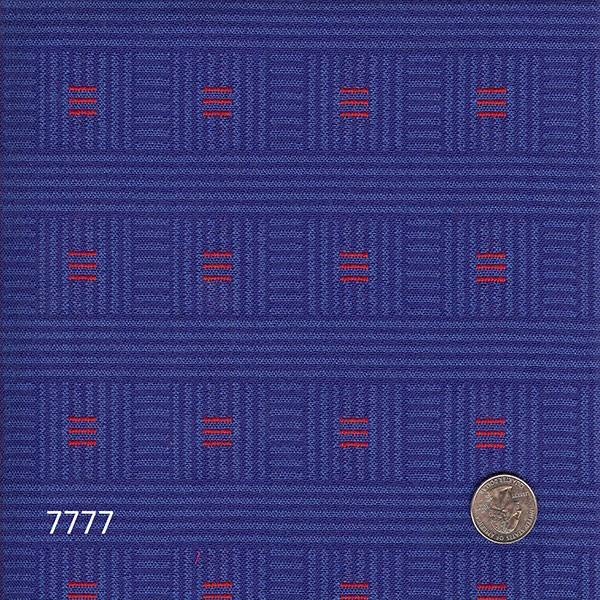

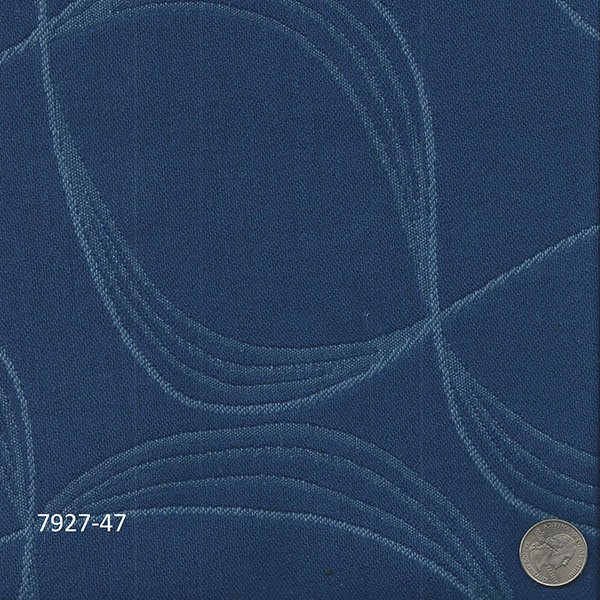

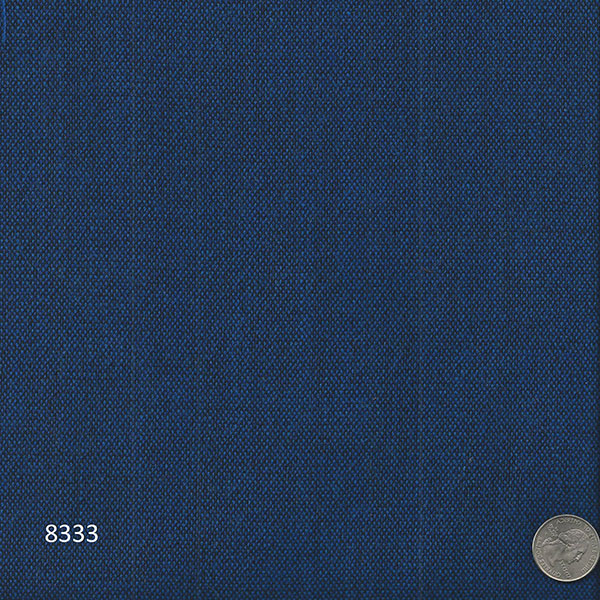

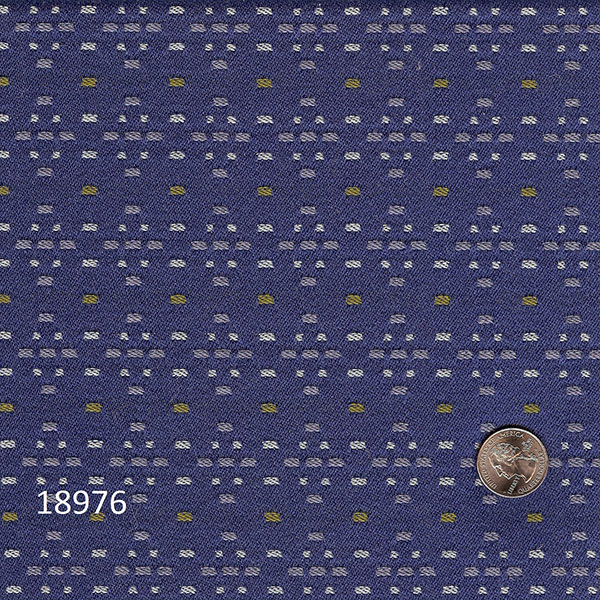

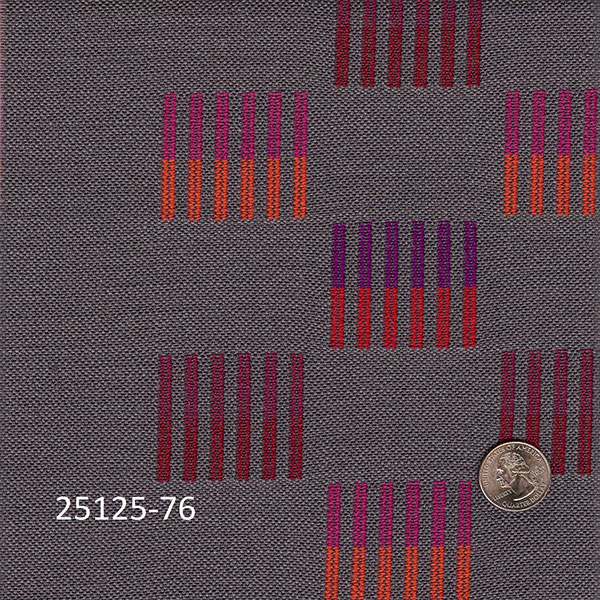

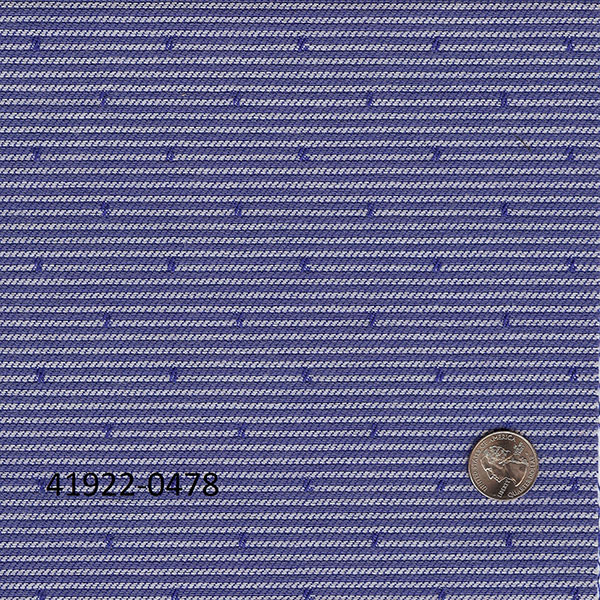

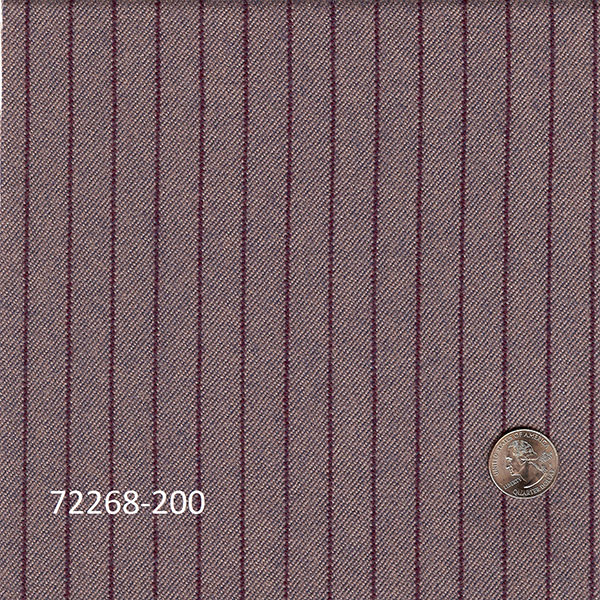

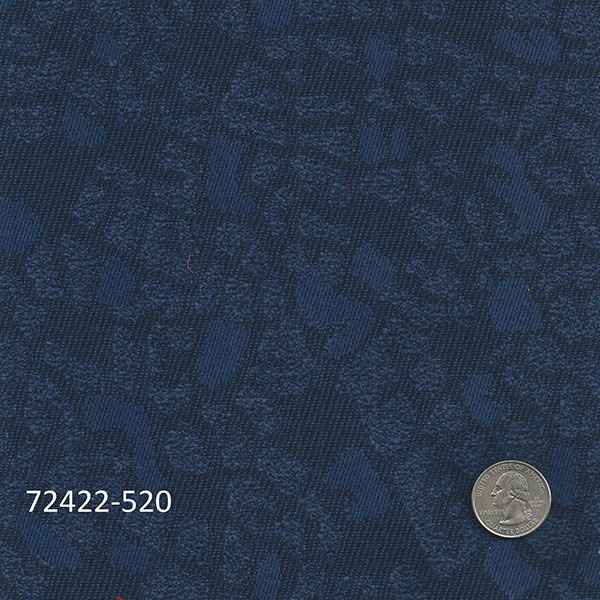

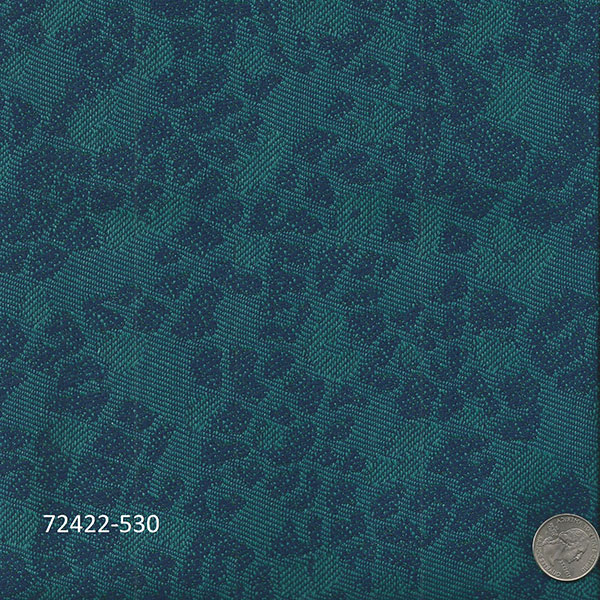

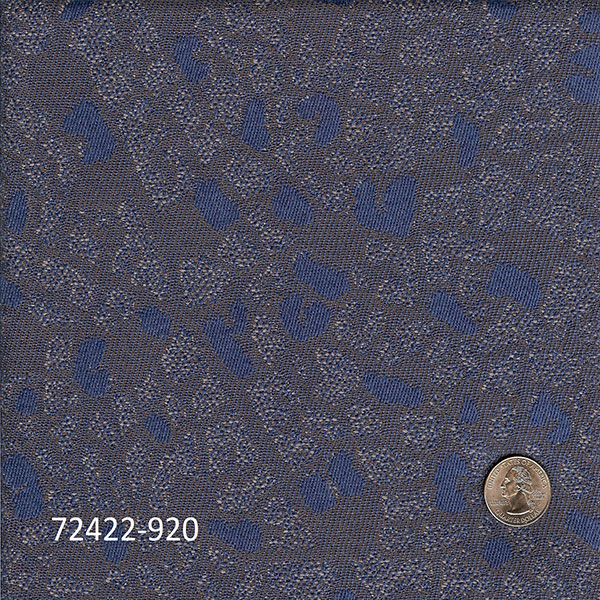

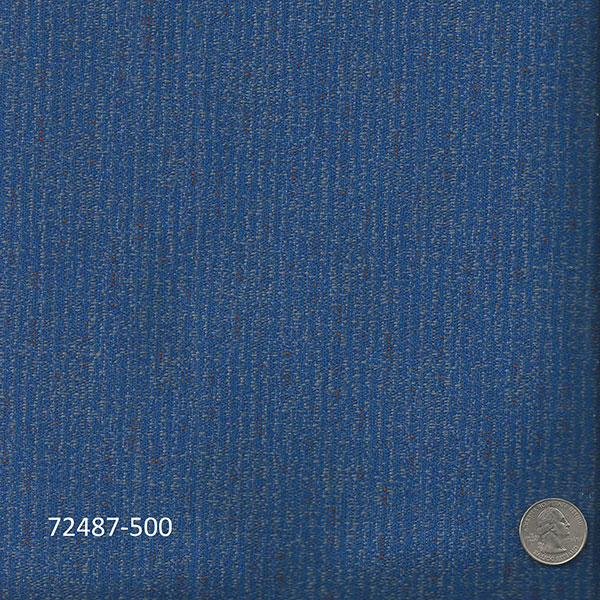

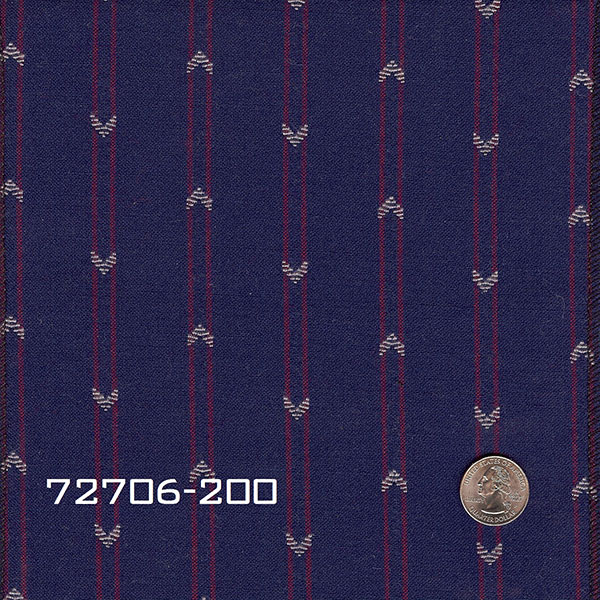

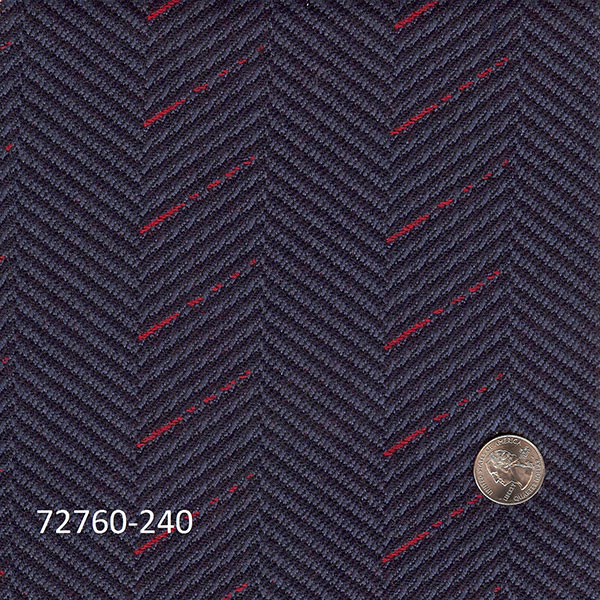

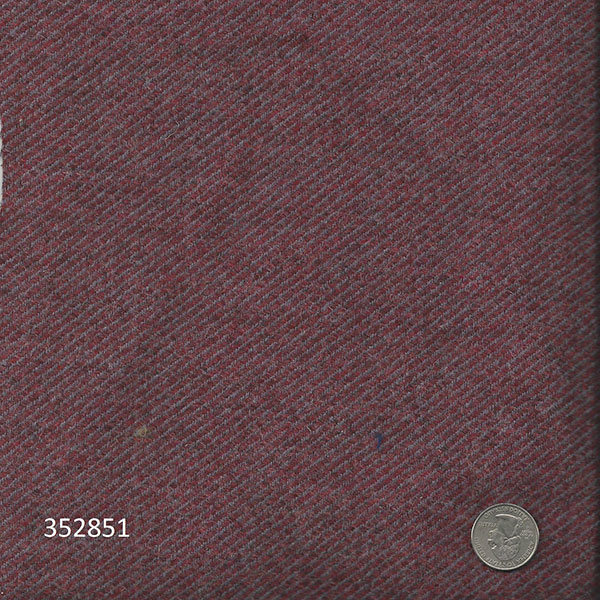

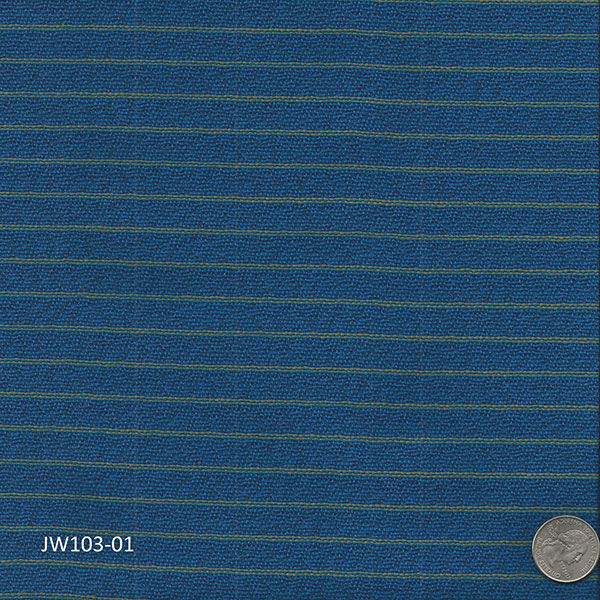

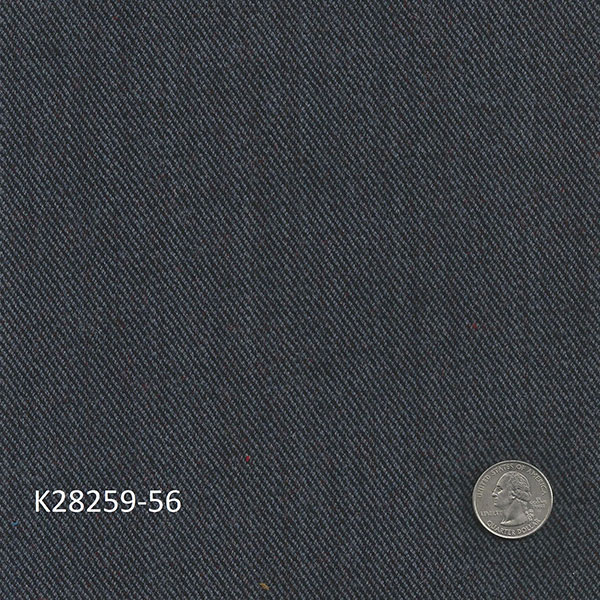

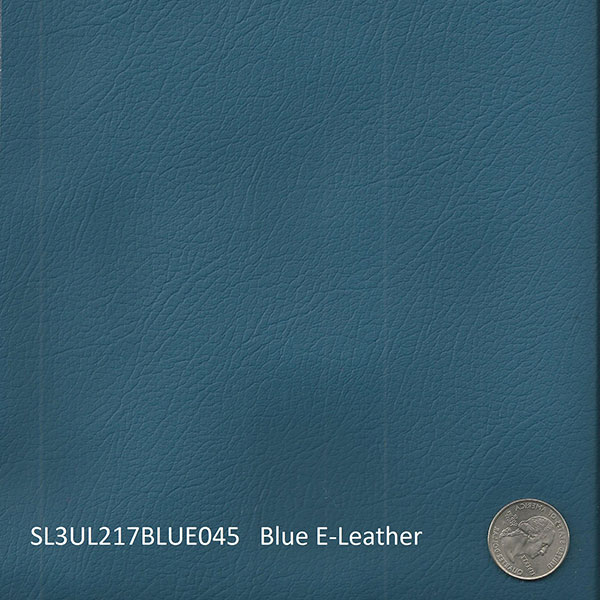

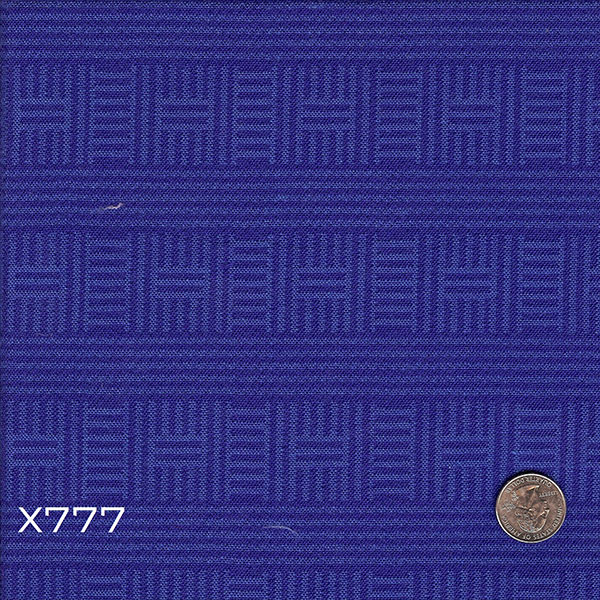

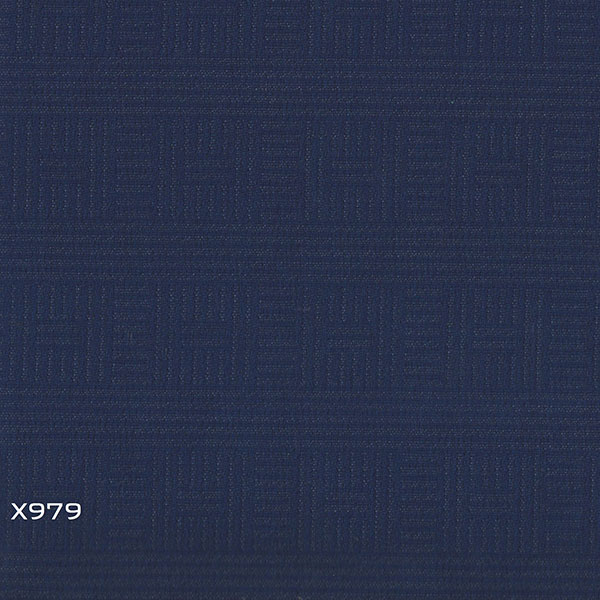

Legacy Aircraft Upholstery Fabric

The vast majority of these fabrics have a content of a minimum of 90% wool fiber, and the remaining content is typically polyamide (nylon).

Wool is the predominant fiber selected for commercial airline seating fabric applications. Why is this so? There are several reasons for this selection. First, wool has inherent flame-resistant properties that help it to conform to the stringent flammability standards required for commercial aircraft seating certifications. The long staple (fiber) length of wool contributes to the strength of the worsted yarns that are woven into these very strong fabrics. This makes these fabrics highly resistant to abrasion which aids in longevity of the seat covers and appearance retention. Finally, wool is a natural fiber that is hydrophilic – it absorbs moisture. Wool fabrics are surprisingly warmer in winter and cooler in summer which makes for a more comfortable seat, particularly on longer-duration flights.

Many of these fabrics are available in quantities that allow the customer to retrofit several ship sets of seats. This may be from utilizing a single fabric for which we have a particularly large inventory, or by combining fabrics that are companions to each other, usually different compatible colors of the same pattern.

Sample swatch books of the Legacy Collection may be requested by upholstery shops, seating MROs and brokers, and aircraft leasing companies that regularly search for in-stock fabrics for seat cover programs.

Legacy fabrics are available only in full roll (50 yards) or half-roll (25 yards) quantities. Smaller cut yardage is not available.